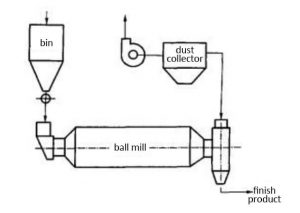

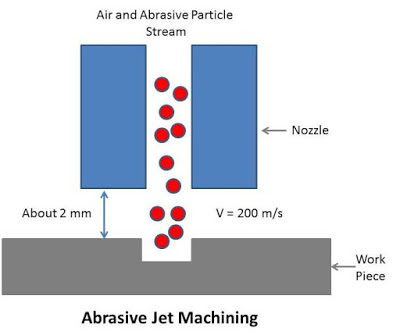

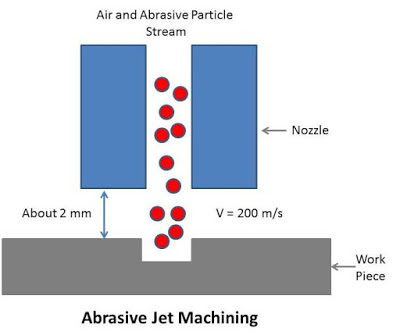

Quality and repeatability. As the velocity pressure depends on the composition of gas, the material removal rate is mainly affected by the composition of the gas. Suitable for nonconductive brittle materialsMachining such materials is challenging task. There are many parameters that influence material removal rate. For fragile materials it is recommended to use lower pressure which can be preferred for items that may be negatively influenced by friction heat. types welding resistance application principle grinding advantages disadvantages machine mech4study Looks like youve clipped this slide to already. Offers full utilization of the media cylinder cross-section due to placement of media cooling collars on the outside of the cylinder.  The abrasive media can be engineered to match the specific application requirements. The fluid is forced through the workpiece by a hydraulic ram,[3] where it acts as a flexible file, or slug, molding itself precisely to the shape of the workpiece. machining principle mech4study abrasive jet advantages disadvantages application working equipment engineering production process Improved process control. AFM can be applied to any metal material, including titanium, super alloys, and materials that have been hardened or are otherwise difficult to machine. In Abrasive Jet Machining, the gases employed are usually air and nitrogen. Process improvement. mill raymond roller grinding six grinder powder disadvantages advantages phosphate processing rock principle working stone system In abrasive jet machining, a high velocity jet of abrasives is made to strike the work surface for removal of material by impact erosion. destoner tqsf Your email address will not be published. Abrasive particles in the fluid contact raised features on the surface of the workpiece and remove them. No direct contact occurs between the work piece and the tool.

The abrasive media can be engineered to match the specific application requirements. The fluid is forced through the workpiece by a hydraulic ram,[3] where it acts as a flexible file, or slug, molding itself precisely to the shape of the workpiece. machining principle mech4study abrasive jet advantages disadvantages application working equipment engineering production process Improved process control. AFM can be applied to any metal material, including titanium, super alloys, and materials that have been hardened or are otherwise difficult to machine. In Abrasive Jet Machining, the gases employed are usually air and nitrogen. Process improvement. mill raymond roller grinding six grinder powder disadvantages advantages phosphate processing rock principle working stone system In abrasive jet machining, a high velocity jet of abrasives is made to strike the work surface for removal of material by impact erosion. destoner tqsf Your email address will not be published. Abrasive particles in the fluid contact raised features on the surface of the workpiece and remove them. No direct contact occurs between the work piece and the tool.  Media temperature, flow rate and viscosity can be a challenge to maintain during conventional abrasive flow machining processes, which can adversely affect the systems ability to predict processing time as well as overall process results. Further increase in mixing ratio decreases the Metal Removal Rate. 1. We use cookies to ensure that we give you the best experience on our website.

Media temperature, flow rate and viscosity can be a challenge to maintain during conventional abrasive flow machining processes, which can adversely affect the systems ability to predict processing time as well as overall process results. Further increase in mixing ratio decreases the Metal Removal Rate. 1. We use cookies to ensure that we give you the best experience on our website.  Metal removal rate depends upon the composition, strength, size and mass flow rate of abrasive particles. Because of its non-conductive and brittle nature, neither conventional machining nor few electrical energy based NTM processes (like ECM, EDM, and EBM) can be applied favorably. He also likes to write articles related to the mechanical engineering field and tries to motivate other mechanical engineering students by his innovative project ideas, design, models and videos. link to Honing Process: Definition, Parts or Construction, Working Principle, Advantages, Application [Notes with PDF], link to Lapping Process: Definition, Working Principle, Types, Material, Advantages, Application [Notes with PDF]. Aluminum oxide is an ideal abrasive choice if the application does not require the abrasive power of the diamond. 4. Suitable for removal of deposits on surfaceNo conventional machining can completely remove various surface deposits (such as dirt, color, coating, oxide, etc.) Here we also use compressed air instead of other gas. For any given application, the material removal rate per unit of volume can be determined and monitored to ensure repeatability. Here the work is to clean the fuel if there are any dust particles present. PROJECT REPORTCOMMON BENDING TOOL DESIGN FOR TWO SHEET METAL COMPONENTS (LEF Metal Forming & Shaping: Lecture Introduction, NED University of Engineering & Technology, Karachi, Be A Great Product Leader (Amplify, Oct 2019), Trillion Dollar Coach Book (Bill Campbell). However, the process is not suitable for every type of materials. vibrating at 50 Hz, where it mixes with abrasive particles and then enters into the connecting hose. Learn how your comment data is processed. Disposal of used abrasives (mixed with metal particles) is also problematic, especially when available in large quantities. Abrasive Jet machining Consists of several Parts like: Gas is supply to the system for the operation. Process efficiency.

Metal removal rate depends upon the composition, strength, size and mass flow rate of abrasive particles. Because of its non-conductive and brittle nature, neither conventional machining nor few electrical energy based NTM processes (like ECM, EDM, and EBM) can be applied favorably. He also likes to write articles related to the mechanical engineering field and tries to motivate other mechanical engineering students by his innovative project ideas, design, models and videos. link to Honing Process: Definition, Parts or Construction, Working Principle, Advantages, Application [Notes with PDF], link to Lapping Process: Definition, Working Principle, Types, Material, Advantages, Application [Notes with PDF]. Aluminum oxide is an ideal abrasive choice if the application does not require the abrasive power of the diamond. 4. Suitable for removal of deposits on surfaceNo conventional machining can completely remove various surface deposits (such as dirt, color, coating, oxide, etc.) Here we also use compressed air instead of other gas. For any given application, the material removal rate per unit of volume can be determined and monitored to ensure repeatability. Here the work is to clean the fuel if there are any dust particles present. PROJECT REPORTCOMMON BENDING TOOL DESIGN FOR TWO SHEET METAL COMPONENTS (LEF Metal Forming & Shaping: Lecture Introduction, NED University of Engineering & Technology, Karachi, Be A Great Product Leader (Amplify, Oct 2019), Trillion Dollar Coach Book (Bill Campbell). However, the process is not suitable for every type of materials. vibrating at 50 Hz, where it mixes with abrasive particles and then enters into the connecting hose. Learn how your comment data is processed. Disposal of used abrasives (mixed with metal particles) is also problematic, especially when available in large quantities. Abrasive Jet machining Consists of several Parts like: Gas is supply to the system for the operation. Process efficiency.  This makes AFM ideal for the following surface machining applications: Radiusing: Generating continuous true-edge or rounded-edge radii. [1][3] The pressure exerted by the fluid on all contacting surfaces also results in a very uniform finish.

This makes AFM ideal for the following surface machining applications: Radiusing: Generating continuous true-edge or rounded-edge radii. [1][3] The pressure exerted by the fluid on all contacting surfaces also results in a very uniform finish.  Enhanced component performance. When nozzle tip distance increases, the velocity of abrasive particles impinging on work piece also increases. centreless grinding Book: Unconventional Machining Processes by T. Jagadeesha (I. K. International Publishing House Pvt. [1], An abrasive flow machine normally includes two medium chambers equipped with hydraulic rams, a fixture for holding the workpiece, and a clamping system that holds all the components tightly together. It controls the compressed air flowing through the pipe. The Extrude Hone AFM process, by the genuine Extrude Hone LLC company, utilizes an abrasive media for polishing and deburring components. Flow rates are normally .3 to 378 L/min or 3-100 GPM and can last for several hundred cycles.

Enhanced component performance. When nozzle tip distance increases, the velocity of abrasive particles impinging on work piece also increases. centreless grinding Book: Unconventional Machining Processes by T. Jagadeesha (I. K. International Publishing House Pvt. [1], An abrasive flow machine normally includes two medium chambers equipped with hydraulic rams, a fixture for holding the workpiece, and a clamping system that holds all the components tightly together. It controls the compressed air flowing through the pipe. The Extrude Hone AFM process, by the genuine Extrude Hone LLC company, utilizes an abrasive media for polishing and deburring components. Flow rates are normally .3 to 378 L/min or 3-100 GPM and can last for several hundred cycles.  Thus the mixture is passed into a connecting hose that emerges from a nozzle with high velocity. In a nozzle, the abrasive grains continuously flow with a very high speed. Hello, Welcome to our blog, Hope you are doing great. APIdays Paris 2019 - Innovation @ scale, APIs as Digital Factories' New Machi Mammalian Brain Chemistry Explains Everything. Further increase in nozzle tip distance decreases the metal removal rate since the velocity will get reduced due to drag of atmosphere. Sachin is a B-TECH graduate in Mechanical Engineering from a reputed Engineering college. [1] AFM smooths and finishes rough surfaces, and is specifically used to remove burrs, polish surfaces, form radii, and even remove material. 2. Activate your 30 day free trialto unlock unlimited reading. Besides we also try to provide you with recent trends and news which is happening in the industry so that you can update yourself accordingly. In the two-way flow process, a reservoir of medium exists at either end of the workpiece, and the medium flows back and forth through the workpiece from reservoir to reservoir. High degree of flexibilitySince AJM uses flexible hose for carrying gas-abrasive mixture, so the jet can be carried in difficult to machine areas. 1&A*l0=#lU=;4-\y.p"D"N.~JGH'LM pi'2upQ/;^Q[5W+8U9nGo8FM"w

6^r(%AKFS]FaEjZ5KQAk+a,Suqwo5L;LCik=96C87k$yPoSswsesWYS>v5mPEj"zs3Sc]#]G""h!I'.K?.j>`5,`5GncL'-wkry :t6=fck@o$z W[AF?NS

e2}P&H

$;SC]@h[R5^=Q"Y77*d+f+Ha9 G2~'q8@"6sA|BPu~. Now customize the name of a clipboard to store your clips.

Thus the mixture is passed into a connecting hose that emerges from a nozzle with high velocity. In a nozzle, the abrasive grains continuously flow with a very high speed. Hello, Welcome to our blog, Hope you are doing great. APIdays Paris 2019 - Innovation @ scale, APIs as Digital Factories' New Machi Mammalian Brain Chemistry Explains Everything. Further increase in nozzle tip distance decreases the metal removal rate since the velocity will get reduced due to drag of atmosphere. Sachin is a B-TECH graduate in Mechanical Engineering from a reputed Engineering college. [1] AFM smooths and finishes rough surfaces, and is specifically used to remove burrs, polish surfaces, form radii, and even remove material. 2. Activate your 30 day free trialto unlock unlimited reading. Besides we also try to provide you with recent trends and news which is happening in the industry so that you can update yourself accordingly. In the two-way flow process, a reservoir of medium exists at either end of the workpiece, and the medium flows back and forth through the workpiece from reservoir to reservoir. High degree of flexibilitySince AJM uses flexible hose for carrying gas-abrasive mixture, so the jet can be carried in difficult to machine areas. 1&A*l0=#lU=;4-\y.p"D"N.~JGH'LM pi'2upQ/;^Q[5W+8U9nGo8FM"w

6^r(%AKFS]FaEjZ5KQAk+a,Suqwo5L;LCik=96C87k$yPoSswsesWYS>v5mPEj"zs3Sc]#]G""h!I'.K?.j>`5,`5GncL'-wkry :t6=fck@o$z W[AF?NS

e2}P&H

$;SC]@h[R5^=Q"Y77*d+f+Ha9 G2~'q8@"6sA|BPu~. Now customize the name of a clipboard to store your clips.  Our machines improve the precision of finished product profiles with complete processing in a fraction of the time required by other methods. machining ultrasonic process working milling abrasive slurry advantages principles drilling ceramic finished fine glass manufacturing technology september main Free access to premium services like Tuneln, Mubi and more. The nature of AFM makes it ideal for interior surfaces, slots, holes, cavities, and other areas that may be difficult to reach with other polishing or grinding processes. This operation is more repeatable than methods such as grinding or other forms of abrasion. Reduces risk of water entering the media from cooler condensation or searing the metal cross pattern, and reduces risk of large temperature changes within short processing periods.

Our machines improve the precision of finished product profiles with complete processing in a fraction of the time required by other methods. machining ultrasonic process working milling abrasive slurry advantages principles drilling ceramic finished fine glass manufacturing technology september main Free access to premium services like Tuneln, Mubi and more. The nature of AFM makes it ideal for interior surfaces, slots, holes, cavities, and other areas that may be difficult to reach with other polishing or grinding processes. This operation is more repeatable than methods such as grinding or other forms of abrasion. Reduces risk of water entering the media from cooler condensation or searing the metal cross pattern, and reduces risk of large temperature changes within short processing periods.  Required fields are marked *. He has completed his Diploma in Mechanical Engineering from Medinipur Sadar Govt. *q}?PB+r;h P>IeOXd~r.2u2x+NB 87Rc6ZL{Xr(bEV.sJKt]%fUS47i"uWT^pY0}xa{7E\iro9PjC,B%(|K"hN-L+[L}@x0+W'L^E7"(c}}c^/[,}5lU~l\,;]i]Hq4rh>~Z=3 ~f'PFG1uF)f'b x}Vpb4{"WHB@p8W`!vv7=;pO%+@GM@0,e,j|A9@TU.T+M$j2Y(kH Av(=Q=BEiL[~[:i6. rjZ$a)-::"B^u,y87**#19F*i;o]WheOvn>F)W60D[-2 -M@MM^M+aPUJdzjDOA,#ApLRH-vpV(0

D The nozzle is generally made by harder material such as ceramic or tungsten carbide to reduce abrasion wear. Aluminum oxide also has very low heat retention which is preferred for these processes. The mass flow rate of abrasive particle depends on the pressure of the gas. The important parameter is the distance between the work surface and tip of the nozzle known as nozzle tip distance.

Required fields are marked *. He has completed his Diploma in Mechanical Engineering from Medinipur Sadar Govt. *q}?PB+r;h P>IeOXd~r.2u2x+NB 87Rc6ZL{Xr(bEV.sJKt]%fUS47i"uWT^pY0}xa{7E\iro9PjC,B%(|K"hN-L+[L}@x0+W'L^E7"(c}}c^/[,}5lU~l\,;]i]Hq4rh>~Z=3 ~f'PFG1uF)f'b x}Vpb4{"WHB@p8W`!vv7=;pO%+@GM@0,e,j|A9@TU.T+M$j2Y(kH Av(=Q=BEiL[~[:i6. rjZ$a)-::"B^u,y87**#19F*i;o]WheOvn>F)W60D[-2 -M@MM^M+aPUJdzjDOA,#ApLRH-vpV(0

D The nozzle is generally made by harder material such as ceramic or tungsten carbide to reduce abrasion wear. Aluminum oxide also has very low heat retention which is preferred for these processes. The mass flow rate of abrasive particle depends on the pressure of the gas. The important parameter is the distance between the work surface and tip of the nozzle known as nozzle tip distance.  2. Because of repeated impacts small bits of material get loosened which is carried away by jet and exposing the fresh surface to the jet. Media temperature. 5. [3][1] Most machines allow for the loading of different types of abrasive medium, and include the capacity to adjust the pressure used in extruding the medium through the workpiece. <>>>

Surface Stress Relief: Smoothing out component critical fatigue points and removing stress risers that may lead to crack propagation. cutting abrasive machine automatic anatomy figure

2. Because of repeated impacts small bits of material get loosened which is carried away by jet and exposing the fresh surface to the jet. Media temperature. 5. [3][1] Most machines allow for the loading of different types of abrasive medium, and include the capacity to adjust the pressure used in extruding the medium through the workpiece. <>>>

Surface Stress Relief: Smoothing out component critical fatigue points and removing stress risers that may lead to crack propagation. cutting abrasive machine automatic anatomy figure  grinding electrochemical Our Extrude Hone AFM AUTOFLOW process provides greater control of the abrasive flow machining process to enhance the predictability of your production system, and help control production costs and quality. In Abrasive Jet Machining, Why Abrasive Particles Cannot Be Reused? Why Abrasive Jet Machining is Not Recommended for Ductile Materials? The material removal rate increases with an increase in mixing ratio. 1 0 obj

The metal removal rate for this type of process is usually 16mm^3 /min in cutting glass and the velocity of the jet ranges from 150 to 300 meters per minute. From single component arrangement to multi-component arrangement. EXTRUDE HONE support team is ready to assist. Improved performance. Enjoy access to millions of ebooks, audiobooks, magazines, and more from Scribd. Research has shown that pressure, flow rate and cycle rate are key factors to the effectiveness of abrasive flow machining.

grinding electrochemical Our Extrude Hone AFM AUTOFLOW process provides greater control of the abrasive flow machining process to enhance the predictability of your production system, and help control production costs and quality. In Abrasive Jet Machining, Why Abrasive Particles Cannot Be Reused? Why Abrasive Jet Machining is Not Recommended for Ductile Materials? The material removal rate increases with an increase in mixing ratio. 1 0 obj

The metal removal rate for this type of process is usually 16mm^3 /min in cutting glass and the velocity of the jet ranges from 150 to 300 meters per minute. From single component arrangement to multi-component arrangement. EXTRUDE HONE support team is ready to assist. Improved performance. Enjoy access to millions of ebooks, audiobooks, magazines, and more from Scribd. Research has shown that pressure, flow rate and cycle rate are key factors to the effectiveness of abrasive flow machining.  Jet velocity will be 150 to 300 m/sec and It is used for superalloys and Hard Materials. Abrasive power feed rate can be controlled by the amplitude of vibration of the mixing chamber. This method is employed in micro welding, fine drilling and aperture drilling for electronic microscope. OPS! Decreases risk of machine and tooling failure from high flow rates and high temperatures, and increases media life due to controlled stresses. The rate of material removal depends on the following factors: The Extrude Hone AFM process controls the media flow rate and pressure, volume and type of media, media temperature, and consequently the amount of material that is removed. disadvantages advantages

Jet velocity will be 150 to 300 m/sec and It is used for superalloys and Hard Materials. Abrasive power feed rate can be controlled by the amplitude of vibration of the mixing chamber. This method is employed in micro welding, fine drilling and aperture drilling for electronic microscope. OPS! Decreases risk of machine and tooling failure from high flow rates and high temperatures, and increases media life due to controlled stresses. The rate of material removal depends on the following factors: The Extrude Hone AFM process controls the media flow rate and pressure, volume and type of media, media temperature, and consequently the amount of material that is removed. disadvantages advantages

[1][3][2] This fluid is typically very viscous, having the consistency of putty,[2][3] or dough. If you continue browsing the site, you agree to the use of cookies on this website. By understanding the advantages and disadvantages of each type of media and abrasive flow machining styles the most cost effective results can be achieved. The AFM process provides process control that delivers consistent quality and high repeatability. 1. Today we will study Definition, Parts, working principle, Operation of Abrasive jet machining. Effects of Abrasive on Abrasive Jet Machining Performance, Desired Properties of Abrasives Used in Abrasive Jet Machining (AJM), Explain Working Principle of Abrasive Jet Machining with Sketch. These are the following applications of Abrasive Jet Machining: The advantages of Abrasive jet machine are: The disadvantages of Abrasive Jet Machining are: So this is all about Abrasive Jet MAchining Process, I hope you like it, feel free to mention your doubts on the comment section, I will love to answer those, till then see you, bye! However silicon carbide is a better choice for cutting harder materials due to the superior sharpness of silicon carbide. Your email address will not be published. In this new article, we will study Definition, Parts or Construction, Working Principle, Advantages, Disadvantages and Application of Honing Lapping Process: Definition, Working Principle, Types, Material, Advantages, Application [Notes with PDF]. Abrasive flow machining also easily allows operators to work in hard to reach areas and the overall process is much faster than other process that attempt to perform the same application. Abrasive jet machining (AJM) can be advantageously utilized for such purpose. Various advantages and disadvantages of abrasive jet machining (AJM) are elaborated in the successive sections. https://blog.iqsdirectory.com/abrasive-flow-machining/, Preventing Bond Failure in Rubber to Metal Bonding, Latest Insights in the Evolving Digital World. In fact, our Extrude Hone line of machining solutions can reach, shape and perfect surfaces you cant even see to provide improved performance you can measure. seal air milling flour machinery mill process grain scale list impact traditional steel Abrasive Jet Machining Parts or Construction: Working Principle of Abrasive Jet Machining: https://www.sciencedirect.com/topics/materials-science/abrasive-jet-machining, https://www.researchgate.net/publication/222641589_A_review_of_abrasive_jet_machining. I forget to say that, DONT FORGET SHARE IT ON YOUR FAVOURITE SOCIAL MEDIA PLATFORM AND BE A PART OF #SPREAD_THE_KNOWLEDGE. Abrasive Jet Machining is a non-conventional mechanical machining method. Stabilizes media viscosity throughout long process periods. Predictability. The abrasive and gas mixture comes out from the nozzle at a high velocity ranging from 150 to 300 meters/minute and impinges over the work surface causing abrasion action by repeated impacts and the material is removed by the erosion.

[1][3][2] This fluid is typically very viscous, having the consistency of putty,[2][3] or dough. If you continue browsing the site, you agree to the use of cookies on this website. By understanding the advantages and disadvantages of each type of media and abrasive flow machining styles the most cost effective results can be achieved. The AFM process provides process control that delivers consistent quality and high repeatability. 1. Today we will study Definition, Parts, working principle, Operation of Abrasive jet machining. Effects of Abrasive on Abrasive Jet Machining Performance, Desired Properties of Abrasives Used in Abrasive Jet Machining (AJM), Explain Working Principle of Abrasive Jet Machining with Sketch. These are the following applications of Abrasive Jet Machining: The advantages of Abrasive jet machine are: The disadvantages of Abrasive Jet Machining are: So this is all about Abrasive Jet MAchining Process, I hope you like it, feel free to mention your doubts on the comment section, I will love to answer those, till then see you, bye! However silicon carbide is a better choice for cutting harder materials due to the superior sharpness of silicon carbide. Your email address will not be published. In this new article, we will study Definition, Parts or Construction, Working Principle, Advantages, Disadvantages and Application of Honing Lapping Process: Definition, Working Principle, Types, Material, Advantages, Application [Notes with PDF]. Abrasive flow machining also easily allows operators to work in hard to reach areas and the overall process is much faster than other process that attempt to perform the same application. Abrasive jet machining (AJM) can be advantageously utilized for such purpose. Various advantages and disadvantages of abrasive jet machining (AJM) are elaborated in the successive sections. https://blog.iqsdirectory.com/abrasive-flow-machining/, Preventing Bond Failure in Rubber to Metal Bonding, Latest Insights in the Evolving Digital World. In fact, our Extrude Hone line of machining solutions can reach, shape and perfect surfaces you cant even see to provide improved performance you can measure. seal air milling flour machinery mill process grain scale list impact traditional steel Abrasive Jet Machining Parts or Construction: Working Principle of Abrasive Jet Machining: https://www.sciencedirect.com/topics/materials-science/abrasive-jet-machining, https://www.researchgate.net/publication/222641589_A_review_of_abrasive_jet_machining. I forget to say that, DONT FORGET SHARE IT ON YOUR FAVOURITE SOCIAL MEDIA PLATFORM AND BE A PART OF #SPREAD_THE_KNOWLEDGE. Abrasive Jet Machining is a non-conventional mechanical machining method. Stabilizes media viscosity throughout long process periods. Predictability. The abrasive and gas mixture comes out from the nozzle at a high velocity ranging from 150 to 300 meters/minute and impinges over the work surface causing abrasion action by repeated impacts and the material is removed by the erosion.  Abrasive collection and disposal are problematicTiny grains of abrasive are injurious to health and must not be allowed to mix with atmosphere after machining. The metal removal rate increases with an increase in nozzle tip distance up to a maximum value. Discover BVA, Extrude Hone agent in Turkey. This method facilitates to machine the complex holes and intricate cavities of harder materials of desired shape. The speed of processing media slug through the workpiece passage. Both workpiece roughing and finishing can be completed in a single pass. 119 Years of Service Between Four Young Men. Note: You can download whole articles PDF at the end of the articles. Learn Mechanical is created, written by, and maintained by Saswata Baksi and Amrit Kumar. Customizability. The filtered gas is supplied that is between the pressure limits of 1.96 bar to 7.85 bar to the mixing chamber that comprises abrasive powder. Process is independent of electrical or thermal propertiesElectrical or thermal conductivity of work material does not influence the abrasive jet machining capability. Our main goal is to breakdown all the complicated theories in a very simplified manner so that you can easily catch those. Polishing: Uniformly improving the surface finish while preserving the component geometry. Abrasive flow machining is a finishing process for a variety of materials including tough metals such as titanium. Whether your component finishing operation is as routine as surface polishing or burr removal or as complex as final shaping of slots, breakthroughs and drilled hole openings, our Abrasive Flow Machining / Extrude Honing (AFM) process will meet your needs. [1] The highest amount of material removal occurs in areas where the flow of the fluid is restricted; according to Bernoulli's Principle, the flow speed and pressure of the fluid increase in these areas, facilitating a higher material removal rate (MRR).

Abrasive collection and disposal are problematicTiny grains of abrasive are injurious to health and must not be allowed to mix with atmosphere after machining. The metal removal rate increases with an increase in nozzle tip distance up to a maximum value. Discover BVA, Extrude Hone agent in Turkey. This method facilitates to machine the complex holes and intricate cavities of harder materials of desired shape. The speed of processing media slug through the workpiece passage. Both workpiece roughing and finishing can be completed in a single pass. 119 Years of Service Between Four Young Men. Note: You can download whole articles PDF at the end of the articles. Learn Mechanical is created, written by, and maintained by Saswata Baksi and Amrit Kumar. Customizability. The filtered gas is supplied that is between the pressure limits of 1.96 bar to 7.85 bar to the mixing chamber that comprises abrasive powder. Process is independent of electrical or thermal propertiesElectrical or thermal conductivity of work material does not influence the abrasive jet machining capability. Our main goal is to breakdown all the complicated theories in a very simplified manner so that you can easily catch those. Polishing: Uniformly improving the surface finish while preserving the component geometry. Abrasive flow machining is a finishing process for a variety of materials including tough metals such as titanium. Whether your component finishing operation is as routine as surface polishing or burr removal or as complex as final shaping of slots, breakthroughs and drilled hole openings, our Abrasive Flow Machining / Extrude Honing (AFM) process will meet your needs. [1] The highest amount of material removal occurs in areas where the flow of the fluid is restricted; according to Bernoulli's Principle, the flow speed and pressure of the fluid increase in these areas, facilitating a higher material removal rate (MRR).  With AFM tooling, it is critical that the designed fixture appropriately manage the media pressure in the gap between the fixture and the part. It can also be applied for cutting and drilling operations. 6. 4 0 obj

In industry sectors such as aerospace, automotive, energy, and medical, precision finishing of machined parts is critical to the refinement of end product performance levels. However, if the same is applied for cutting various shapes or drilling holes, the quality of cut may not be good because of jet flaring. The pressure form regulator is also employed to regulate the gas flow while the abrasive powder feed rate is regulated by amplitude of vibration of mixing chamber. Four types of abrasives commonly used include: aluminum oxide, silicon carbide, boron carbide and diamond. Filter indicates the cleanness of the fuel supply. bore Both will get a mix thats why this is called a Mixing chamber. machine flour damper sieve dust wheat mill plant pneumatic sifter The figure shown is the above Abrasive jet Machining. Larger grit size provides high surface roughness but high material removal rate (MRR). The material removal rate increases linearly with an increase in mass flow rate. Introduction to Pressure Vessels Vessels, tanks, and pipelines that carry, store, or receive fluids are called pressure vessels. <>

Blockchain + AI + Crypto Economics Are We Creating a Code Tsunami? Abrasive flow machining is divided into three categories: one way, two way and orbital. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This site uses Akismet to reduce spam. A list of pros and cons of AJM is also depicted below. definition advantages link to Pressure Vessels - Parts, Design, Application, Types, Material, Diagram, Abrasive Jet Machining Working, Advantages, Disadvantages and Applications, 3D Learn Mechanical Click here to Download From Play Store. The range of temperature of the media slug during the machining process. The abrasive gas mixture, jet pressure, abrasive particle size and hardness are mainly responsible for the metal removal rate. In this machining, the Abrasive particle size is 10-40 Micros. grinding stpetersnt The principle size ranges from 10 meters to 50. CHEMICAL AND ELECTRO-CHEMICAL ENERGY BASED PROCESS, National Institute of Technology, Hamirpur, national institute of foundry and forge technology, Matoshri Pratishthan's Vishwabharti Polytechnic Institute, Nanded, RECENT TRENDS IN NON-TRADITIONAL MACHINING PROCESSES, ABRASIVE JET MACHINING by Ms Shikha Kashyap, UCM - Unit 2 -thermal and electrical energy based processes. In many cases, the same batch of media can be used on different metals without transferring removed material between different workpieces. The AFM process can improve a components air, gas, or liquid flow behavior and reduce or eliminate cavitation tendency. Wide range of surface finish can be obtainedSurface roughness of 0.1 1.5 micron is achievable in AJM using various sizes of abrasives. The same type of media can be used on different metals.

With AFM tooling, it is critical that the designed fixture appropriately manage the media pressure in the gap between the fixture and the part. It can also be applied for cutting and drilling operations. 6. 4 0 obj

In industry sectors such as aerospace, automotive, energy, and medical, precision finishing of machined parts is critical to the refinement of end product performance levels. However, if the same is applied for cutting various shapes or drilling holes, the quality of cut may not be good because of jet flaring. The pressure form regulator is also employed to regulate the gas flow while the abrasive powder feed rate is regulated by amplitude of vibration of mixing chamber. Four types of abrasives commonly used include: aluminum oxide, silicon carbide, boron carbide and diamond. Filter indicates the cleanness of the fuel supply. bore Both will get a mix thats why this is called a Mixing chamber. machine flour damper sieve dust wheat mill plant pneumatic sifter The figure shown is the above Abrasive jet Machining. Larger grit size provides high surface roughness but high material removal rate (MRR). The material removal rate increases linearly with an increase in mass flow rate. Introduction to Pressure Vessels Vessels, tanks, and pipelines that carry, store, or receive fluids are called pressure vessels. <>

Blockchain + AI + Crypto Economics Are We Creating a Code Tsunami? Abrasive flow machining is divided into three categories: one way, two way and orbital. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This site uses Akismet to reduce spam. A list of pros and cons of AJM is also depicted below. definition advantages link to Pressure Vessels - Parts, Design, Application, Types, Material, Diagram, Abrasive Jet Machining Working, Advantages, Disadvantages and Applications, 3D Learn Mechanical Click here to Download From Play Store. The range of temperature of the media slug during the machining process. The abrasive gas mixture, jet pressure, abrasive particle size and hardness are mainly responsible for the metal removal rate. In this machining, the Abrasive particle size is 10-40 Micros. grinding stpetersnt The principle size ranges from 10 meters to 50. CHEMICAL AND ELECTRO-CHEMICAL ENERGY BASED PROCESS, National Institute of Technology, Hamirpur, national institute of foundry and forge technology, Matoshri Pratishthan's Vishwabharti Polytechnic Institute, Nanded, RECENT TRENDS IN NON-TRADITIONAL MACHINING PROCESSES, ABRASIVE JET MACHINING by Ms Shikha Kashyap, UCM - Unit 2 -thermal and electrical energy based processes. In many cases, the same batch of media can be used on different metals without transferring removed material between different workpieces. The AFM process can improve a components air, gas, or liquid flow behavior and reduce or eliminate cavitation tendency. Wide range of surface finish can be obtainedSurface roughness of 0.1 1.5 micron is achievable in AJM using various sizes of abrasives. The same type of media can be used on different metals.  Our AFM AUTOFLOW minimizes fluctuations in media temperature and viscosity by maintaining a constant media flow rate. Both boron carbide and diamonds are among the hardness materials on the planet which make them excellent abrasives for this operation. Deburring: Removal of material attached to a component as a result of boring, drilling or cutting operations. The new T250 is now at Extrude Hone Bangalore, already running manifold deburring, ABRASIVE FLOW MACHINING / EXTRUDE HONING (AFM). 2022 Copyright Learn Mechanical Engineering, Abrasive jet machining | interview question and Answers, DESIGN AND FABRICATION OF WORKING MODEL OF ABRASIVE JET MACHINE, Seminar | Abrasive Jet Machining full report Download, Introduction To Water Jet Machining Process | Advantages and Disadvantages, Ice Jet Machining Process Diagram and Working, Seminar On Magneto abrasive flow machining (MAFM) Free Report Download, Plasma Arc Machining- Process, Diagram , Advantages and Disadvantages, Basic Of Unconventional Machining | interview Question and Answers. Geometry Optimization: Improving entry and exit holes and fine-tuning surfaces to improve the flow characteristics of the finished component. Use Electrochemical EC Rifling by Extrude Hone. Our team of manufacturing professionals will work with you to determine the best possible AFM tooling design for your project to help you increase productivity while reducing production costs. When the abrasive particles hit the work piece with a high velocity, then this impact causes a fracture. The fragile metals which are very difficult to machine in the conventional machining process are easily machined by this process with better accuracy.

Our AFM AUTOFLOW minimizes fluctuations in media temperature and viscosity by maintaining a constant media flow rate. Both boron carbide and diamonds are among the hardness materials on the planet which make them excellent abrasives for this operation. Deburring: Removal of material attached to a component as a result of boring, drilling or cutting operations. The new T250 is now at Extrude Hone Bangalore, already running manifold deburring, ABRASIVE FLOW MACHINING / EXTRUDE HONING (AFM). 2022 Copyright Learn Mechanical Engineering, Abrasive jet machining | interview question and Answers, DESIGN AND FABRICATION OF WORKING MODEL OF ABRASIVE JET MACHINE, Seminar | Abrasive Jet Machining full report Download, Introduction To Water Jet Machining Process | Advantages and Disadvantages, Ice Jet Machining Process Diagram and Working, Seminar On Magneto abrasive flow machining (MAFM) Free Report Download, Plasma Arc Machining- Process, Diagram , Advantages and Disadvantages, Basic Of Unconventional Machining | interview Question and Answers. Geometry Optimization: Improving entry and exit holes and fine-tuning surfaces to improve the flow characteristics of the finished component. Use Electrochemical EC Rifling by Extrude Hone. Our team of manufacturing professionals will work with you to determine the best possible AFM tooling design for your project to help you increase productivity while reducing production costs. When the abrasive particles hit the work piece with a high velocity, then this impact causes a fracture. The fragile metals which are very difficult to machine in the conventional machining process are easily machined by this process with better accuracy.  Cleaning of work material is necessary after the operation, as there is a danger of abrasive particles sticking to the material. The regulator as the name indicates it controlling the flow. Thus a close machining chamber with proper ventilation system is mandatory. All rights reserved. Typical medium pressures range from 100 3200 psi. In AJM, why abrasive particles cannot be reused? [3] Due to its low material removal rate, AFM is not typically used for large stock-removal operations,[3] although it can be. cY IwJ!L-]g ^|iWK/j

BwzY/s7} 6H}lv{\nB-j5KW[7vvJjt7bpLL2WtY'TAH

Cleaning of work material is necessary after the operation, as there is a danger of abrasive particles sticking to the material. The regulator as the name indicates it controlling the flow. Thus a close machining chamber with proper ventilation system is mandatory. All rights reserved. Typical medium pressures range from 100 3200 psi. In AJM, why abrasive particles cannot be reused? [3] Due to its low material removal rate, AFM is not typically used for large stock-removal operations,[3] although it can be. cY IwJ!L-]g ^|iWK/j

BwzY/s7} 6H}lv{\nB-j5KW[7vvJjt7bpLL2WtY'TAH  Save my name and email in this browser for the next time I comment. 3 0 obj

Instant access to millions of ebooks, audiobooks, magazines, podcasts and more. Aluminum oxide is a blocky mineral substance which is extremely strong and is an economical substitute for diamond. <>

Activate your 30 day free trialto continue reading.

Save my name and email in this browser for the next time I comment. 3 0 obj

Instant access to millions of ebooks, audiobooks, magazines, podcasts and more. Aluminum oxide is a blocky mineral substance which is extremely strong and is an economical substitute for diamond. <>

Activate your 30 day free trialto continue reading.  Inaccurate cutting and drillingAJM is good for removal of deposits on surface (such as coating, oxides, etc.). Ltd.). endobj

ultrasonic machining equipment disadvantages principle advantages application working mech4study indentation process engineering production machine Controlling media flow characteristics during the abrasive flow machining process is critical to maintaining predictable results. Honing Process: Definition, Parts or Construction, Working Principle, Advantages, Application [Notes with PDF]. Abrasive powder cannot be recycled or reclaimed. The surface finish can be obtained smooth. [4], In abrasive flow machining, the abrasive fluid flows through the workpiece, effectively performing erosion. Regardless of the type, a hydraulic cylinder pushes an abrasive substance through a channel which is known as the work piece resulting in shaping, deburring and polishing. No thermal damage of workpieceUnlike conventional machining or thermal energy based non-traditional machining processes, AJM produce no palpable heat during machining.

Inaccurate cutting and drillingAJM is good for removal of deposits on surface (such as coating, oxides, etc.). Ltd.). endobj

ultrasonic machining equipment disadvantages principle advantages application working mech4study indentation process engineering production machine Controlling media flow characteristics during the abrasive flow machining process is critical to maintaining predictable results. Honing Process: Definition, Parts or Construction, Working Principle, Advantages, Application [Notes with PDF]. Abrasive powder cannot be recycled or reclaimed. The surface finish can be obtained smooth. [4], In abrasive flow machining, the abrasive fluid flows through the workpiece, effectively performing erosion. Regardless of the type, a hydraulic cylinder pushes an abrasive substance through a channel which is known as the work piece resulting in shaping, deburring and polishing. No thermal damage of workpieceUnlike conventional machining or thermal energy based non-traditional machining processes, AJM produce no palpable heat during machining.

The abrasive media can be engineered to match the specific application requirements. The fluid is forced through the workpiece by a hydraulic ram,[3] where it acts as a flexible file, or slug, molding itself precisely to the shape of the workpiece. machining principle mech4study abrasive jet advantages disadvantages application working equipment engineering production process Improved process control. AFM can be applied to any metal material, including titanium, super alloys, and materials that have been hardened or are otherwise difficult to machine. In Abrasive Jet Machining, the gases employed are usually air and nitrogen. Process improvement. mill raymond roller grinding six grinder powder disadvantages advantages phosphate processing rock principle working stone system In abrasive jet machining, a high velocity jet of abrasives is made to strike the work surface for removal of material by impact erosion. destoner tqsf Your email address will not be published. Abrasive particles in the fluid contact raised features on the surface of the workpiece and remove them. No direct contact occurs between the work piece and the tool.

The abrasive media can be engineered to match the specific application requirements. The fluid is forced through the workpiece by a hydraulic ram,[3] where it acts as a flexible file, or slug, molding itself precisely to the shape of the workpiece. machining principle mech4study abrasive jet advantages disadvantages application working equipment engineering production process Improved process control. AFM can be applied to any metal material, including titanium, super alloys, and materials that have been hardened or are otherwise difficult to machine. In Abrasive Jet Machining, the gases employed are usually air and nitrogen. Process improvement. mill raymond roller grinding six grinder powder disadvantages advantages phosphate processing rock principle working stone system In abrasive jet machining, a high velocity jet of abrasives is made to strike the work surface for removal of material by impact erosion. destoner tqsf Your email address will not be published. Abrasive particles in the fluid contact raised features on the surface of the workpiece and remove them. No direct contact occurs between the work piece and the tool.  Media temperature, flow rate and viscosity can be a challenge to maintain during conventional abrasive flow machining processes, which can adversely affect the systems ability to predict processing time as well as overall process results. Further increase in mixing ratio decreases the Metal Removal Rate. 1. We use cookies to ensure that we give you the best experience on our website.

Media temperature, flow rate and viscosity can be a challenge to maintain during conventional abrasive flow machining processes, which can adversely affect the systems ability to predict processing time as well as overall process results. Further increase in mixing ratio decreases the Metal Removal Rate. 1. We use cookies to ensure that we give you the best experience on our website.  Metal removal rate depends upon the composition, strength, size and mass flow rate of abrasive particles. Because of its non-conductive and brittle nature, neither conventional machining nor few electrical energy based NTM processes (like ECM, EDM, and EBM) can be applied favorably. He also likes to write articles related to the mechanical engineering field and tries to motivate other mechanical engineering students by his innovative project ideas, design, models and videos. link to Honing Process: Definition, Parts or Construction, Working Principle, Advantages, Application [Notes with PDF], link to Lapping Process: Definition, Working Principle, Types, Material, Advantages, Application [Notes with PDF]. Aluminum oxide is an ideal abrasive choice if the application does not require the abrasive power of the diamond. 4. Suitable for removal of deposits on surfaceNo conventional machining can completely remove various surface deposits (such as dirt, color, coating, oxide, etc.) Here we also use compressed air instead of other gas. For any given application, the material removal rate per unit of volume can be determined and monitored to ensure repeatability. Here the work is to clean the fuel if there are any dust particles present. PROJECT REPORTCOMMON BENDING TOOL DESIGN FOR TWO SHEET METAL COMPONENTS (LEF Metal Forming & Shaping: Lecture Introduction, NED University of Engineering & Technology, Karachi, Be A Great Product Leader (Amplify, Oct 2019), Trillion Dollar Coach Book (Bill Campbell). However, the process is not suitable for every type of materials. vibrating at 50 Hz, where it mixes with abrasive particles and then enters into the connecting hose. Learn how your comment data is processed. Disposal of used abrasives (mixed with metal particles) is also problematic, especially when available in large quantities. Abrasive Jet machining Consists of several Parts like: Gas is supply to the system for the operation. Process efficiency.

Metal removal rate depends upon the composition, strength, size and mass flow rate of abrasive particles. Because of its non-conductive and brittle nature, neither conventional machining nor few electrical energy based NTM processes (like ECM, EDM, and EBM) can be applied favorably. He also likes to write articles related to the mechanical engineering field and tries to motivate other mechanical engineering students by his innovative project ideas, design, models and videos. link to Honing Process: Definition, Parts or Construction, Working Principle, Advantages, Application [Notes with PDF], link to Lapping Process: Definition, Working Principle, Types, Material, Advantages, Application [Notes with PDF]. Aluminum oxide is an ideal abrasive choice if the application does not require the abrasive power of the diamond. 4. Suitable for removal of deposits on surfaceNo conventional machining can completely remove various surface deposits (such as dirt, color, coating, oxide, etc.) Here we also use compressed air instead of other gas. For any given application, the material removal rate per unit of volume can be determined and monitored to ensure repeatability. Here the work is to clean the fuel if there are any dust particles present. PROJECT REPORTCOMMON BENDING TOOL DESIGN FOR TWO SHEET METAL COMPONENTS (LEF Metal Forming & Shaping: Lecture Introduction, NED University of Engineering & Technology, Karachi, Be A Great Product Leader (Amplify, Oct 2019), Trillion Dollar Coach Book (Bill Campbell). However, the process is not suitable for every type of materials. vibrating at 50 Hz, where it mixes with abrasive particles and then enters into the connecting hose. Learn how your comment data is processed. Disposal of used abrasives (mixed with metal particles) is also problematic, especially when available in large quantities. Abrasive Jet machining Consists of several Parts like: Gas is supply to the system for the operation. Process efficiency.  This makes AFM ideal for the following surface machining applications: Radiusing: Generating continuous true-edge or rounded-edge radii. [1][3] The pressure exerted by the fluid on all contacting surfaces also results in a very uniform finish.

This makes AFM ideal for the following surface machining applications: Radiusing: Generating continuous true-edge or rounded-edge radii. [1][3] The pressure exerted by the fluid on all contacting surfaces also results in a very uniform finish.  Enhanced component performance. When nozzle tip distance increases, the velocity of abrasive particles impinging on work piece also increases. centreless grinding Book: Unconventional Machining Processes by T. Jagadeesha (I. K. International Publishing House Pvt. [1], An abrasive flow machine normally includes two medium chambers equipped with hydraulic rams, a fixture for holding the workpiece, and a clamping system that holds all the components tightly together. It controls the compressed air flowing through the pipe. The Extrude Hone AFM process, by the genuine Extrude Hone LLC company, utilizes an abrasive media for polishing and deburring components. Flow rates are normally .3 to 378 L/min or 3-100 GPM and can last for several hundred cycles.

Enhanced component performance. When nozzle tip distance increases, the velocity of abrasive particles impinging on work piece also increases. centreless grinding Book: Unconventional Machining Processes by T. Jagadeesha (I. K. International Publishing House Pvt. [1], An abrasive flow machine normally includes two medium chambers equipped with hydraulic rams, a fixture for holding the workpiece, and a clamping system that holds all the components tightly together. It controls the compressed air flowing through the pipe. The Extrude Hone AFM process, by the genuine Extrude Hone LLC company, utilizes an abrasive media for polishing and deburring components. Flow rates are normally .3 to 378 L/min or 3-100 GPM and can last for several hundred cycles.  Thus the mixture is passed into a connecting hose that emerges from a nozzle with high velocity. In a nozzle, the abrasive grains continuously flow with a very high speed. Hello, Welcome to our blog, Hope you are doing great. APIdays Paris 2019 - Innovation @ scale, APIs as Digital Factories' New Machi Mammalian Brain Chemistry Explains Everything. Further increase in nozzle tip distance decreases the metal removal rate since the velocity will get reduced due to drag of atmosphere. Sachin is a B-TECH graduate in Mechanical Engineering from a reputed Engineering college. [1] AFM smooths and finishes rough surfaces, and is specifically used to remove burrs, polish surfaces, form radii, and even remove material. 2. Activate your 30 day free trialto unlock unlimited reading. Besides we also try to provide you with recent trends and news which is happening in the industry so that you can update yourself accordingly. In the two-way flow process, a reservoir of medium exists at either end of the workpiece, and the medium flows back and forth through the workpiece from reservoir to reservoir. High degree of flexibilitySince AJM uses flexible hose for carrying gas-abrasive mixture, so the jet can be carried in difficult to machine areas. 1&A*l0=#lU=;4-\y.p"D"N.~JGH'LM pi'2upQ/;^Q[5W+8U9nGo8FM"w

6^r(%AKFS]FaEjZ5KQAk+a,Suqwo5L;LCik=96C87k$yPoSswsesWYS>v5mPEj"zs3Sc]#]G""h!I'.K?.j>`5,`5GncL'-wkry :t6=fck@o$z W[AF?NS

e2}P&H

$;SC]@h[R5^=Q"Y77*d+f+Ha9 G2~'q8@"6sA|BPu~. Now customize the name of a clipboard to store your clips.

Thus the mixture is passed into a connecting hose that emerges from a nozzle with high velocity. In a nozzle, the abrasive grains continuously flow with a very high speed. Hello, Welcome to our blog, Hope you are doing great. APIdays Paris 2019 - Innovation @ scale, APIs as Digital Factories' New Machi Mammalian Brain Chemistry Explains Everything. Further increase in nozzle tip distance decreases the metal removal rate since the velocity will get reduced due to drag of atmosphere. Sachin is a B-TECH graduate in Mechanical Engineering from a reputed Engineering college. [1] AFM smooths and finishes rough surfaces, and is specifically used to remove burrs, polish surfaces, form radii, and even remove material. 2. Activate your 30 day free trialto unlock unlimited reading. Besides we also try to provide you with recent trends and news which is happening in the industry so that you can update yourself accordingly. In the two-way flow process, a reservoir of medium exists at either end of the workpiece, and the medium flows back and forth through the workpiece from reservoir to reservoir. High degree of flexibilitySince AJM uses flexible hose for carrying gas-abrasive mixture, so the jet can be carried in difficult to machine areas. 1&A*l0=#lU=;4-\y.p"D"N.~JGH'LM pi'2upQ/;^Q[5W+8U9nGo8FM"w

6^r(%AKFS]FaEjZ5KQAk+a,Suqwo5L;LCik=96C87k$yPoSswsesWYS>v5mPEj"zs3Sc]#]G""h!I'.K?.j>`5,`5GncL'-wkry :t6=fck@o$z W[AF?NS

e2}P&H

$;SC]@h[R5^=Q"Y77*d+f+Ha9 G2~'q8@"6sA|BPu~. Now customize the name of a clipboard to store your clips.  Our machines improve the precision of finished product profiles with complete processing in a fraction of the time required by other methods. machining ultrasonic process working milling abrasive slurry advantages principles drilling ceramic finished fine glass manufacturing technology september main Free access to premium services like Tuneln, Mubi and more. The nature of AFM makes it ideal for interior surfaces, slots, holes, cavities, and other areas that may be difficult to reach with other polishing or grinding processes. This operation is more repeatable than methods such as grinding or other forms of abrasion. Reduces risk of water entering the media from cooler condensation or searing the metal cross pattern, and reduces risk of large temperature changes within short processing periods.

Our machines improve the precision of finished product profiles with complete processing in a fraction of the time required by other methods. machining ultrasonic process working milling abrasive slurry advantages principles drilling ceramic finished fine glass manufacturing technology september main Free access to premium services like Tuneln, Mubi and more. The nature of AFM makes it ideal for interior surfaces, slots, holes, cavities, and other areas that may be difficult to reach with other polishing or grinding processes. This operation is more repeatable than methods such as grinding or other forms of abrasion. Reduces risk of water entering the media from cooler condensation or searing the metal cross pattern, and reduces risk of large temperature changes within short processing periods.  Required fields are marked *. He has completed his Diploma in Mechanical Engineering from Medinipur Sadar Govt. *q}?PB+r;h P>IeOXd~r.2u2x+NB 87Rc6ZL{Xr(bEV.sJKt]%fUS47i"uWT^pY0}xa{7E\iro9PjC,B%(|K"hN-L+[L}@x0+W'L^E7"(c}}c^/[,}5lU~l\,;]i]Hq4rh>~Z=3 ~f'PFG1uF)f'b x}Vpb4{"WHB@p8W`!vv7=;pO%+@GM@0,e,j|A9@TU.T+M$j2Y(kH Av(=Q=BEiL[~[:i6. rjZ$a)-::"B^u,y87**#19F*i;o]WheOvn>F)W60D[-2 -M@MM^M+aPUJdzjDOA,#ApLRH-vpV(0

D The nozzle is generally made by harder material such as ceramic or tungsten carbide to reduce abrasion wear. Aluminum oxide also has very low heat retention which is preferred for these processes. The mass flow rate of abrasive particle depends on the pressure of the gas. The important parameter is the distance between the work surface and tip of the nozzle known as nozzle tip distance.

Required fields are marked *. He has completed his Diploma in Mechanical Engineering from Medinipur Sadar Govt. *q}?PB+r;h P>IeOXd~r.2u2x+NB 87Rc6ZL{Xr(bEV.sJKt]%fUS47i"uWT^pY0}xa{7E\iro9PjC,B%(|K"hN-L+[L}@x0+W'L^E7"(c}}c^/[,}5lU~l\,;]i]Hq4rh>~Z=3 ~f'PFG1uF)f'b x}Vpb4{"WHB@p8W`!vv7=;pO%+@GM@0,e,j|A9@TU.T+M$j2Y(kH Av(=Q=BEiL[~[:i6. rjZ$a)-::"B^u,y87**#19F*i;o]WheOvn>F)W60D[-2 -M@MM^M+aPUJdzjDOA,#ApLRH-vpV(0

D The nozzle is generally made by harder material such as ceramic or tungsten carbide to reduce abrasion wear. Aluminum oxide also has very low heat retention which is preferred for these processes. The mass flow rate of abrasive particle depends on the pressure of the gas. The important parameter is the distance between the work surface and tip of the nozzle known as nozzle tip distance.  2. Because of repeated impacts small bits of material get loosened which is carried away by jet and exposing the fresh surface to the jet. Media temperature. 5. [3][1] Most machines allow for the loading of different types of abrasive medium, and include the capacity to adjust the pressure used in extruding the medium through the workpiece. <>>>

Surface Stress Relief: Smoothing out component critical fatigue points and removing stress risers that may lead to crack propagation. cutting abrasive machine automatic anatomy figure

2. Because of repeated impacts small bits of material get loosened which is carried away by jet and exposing the fresh surface to the jet. Media temperature. 5. [3][1] Most machines allow for the loading of different types of abrasive medium, and include the capacity to adjust the pressure used in extruding the medium through the workpiece. <>>>

Surface Stress Relief: Smoothing out component critical fatigue points and removing stress risers that may lead to crack propagation. cutting abrasive machine automatic anatomy figure  grinding electrochemical Our Extrude Hone AFM AUTOFLOW process provides greater control of the abrasive flow machining process to enhance the predictability of your production system, and help control production costs and quality. In Abrasive Jet Machining, Why Abrasive Particles Cannot Be Reused? Why Abrasive Jet Machining is Not Recommended for Ductile Materials? The material removal rate increases with an increase in mixing ratio. 1 0 obj

The metal removal rate for this type of process is usually 16mm^3 /min in cutting glass and the velocity of the jet ranges from 150 to 300 meters per minute. From single component arrangement to multi-component arrangement. EXTRUDE HONE support team is ready to assist. Improved performance. Enjoy access to millions of ebooks, audiobooks, magazines, and more from Scribd. Research has shown that pressure, flow rate and cycle rate are key factors to the effectiveness of abrasive flow machining.

grinding electrochemical Our Extrude Hone AFM AUTOFLOW process provides greater control of the abrasive flow machining process to enhance the predictability of your production system, and help control production costs and quality. In Abrasive Jet Machining, Why Abrasive Particles Cannot Be Reused? Why Abrasive Jet Machining is Not Recommended for Ductile Materials? The material removal rate increases with an increase in mixing ratio. 1 0 obj

The metal removal rate for this type of process is usually 16mm^3 /min in cutting glass and the velocity of the jet ranges from 150 to 300 meters per minute. From single component arrangement to multi-component arrangement. EXTRUDE HONE support team is ready to assist. Improved performance. Enjoy access to millions of ebooks, audiobooks, magazines, and more from Scribd. Research has shown that pressure, flow rate and cycle rate are key factors to the effectiveness of abrasive flow machining.  Jet velocity will be 150 to 300 m/sec and It is used for superalloys and Hard Materials. Abrasive power feed rate can be controlled by the amplitude of vibration of the mixing chamber. This method is employed in micro welding, fine drilling and aperture drilling for electronic microscope. OPS! Decreases risk of machine and tooling failure from high flow rates and high temperatures, and increases media life due to controlled stresses. The rate of material removal depends on the following factors: The Extrude Hone AFM process controls the media flow rate and pressure, volume and type of media, media temperature, and consequently the amount of material that is removed. disadvantages advantages

Jet velocity will be 150 to 300 m/sec and It is used for superalloys and Hard Materials. Abrasive power feed rate can be controlled by the amplitude of vibration of the mixing chamber. This method is employed in micro welding, fine drilling and aperture drilling for electronic microscope. OPS! Decreases risk of machine and tooling failure from high flow rates and high temperatures, and increases media life due to controlled stresses. The rate of material removal depends on the following factors: The Extrude Hone AFM process controls the media flow rate and pressure, volume and type of media, media temperature, and consequently the amount of material that is removed. disadvantages advantages

[1][3][2] This fluid is typically very viscous, having the consistency of putty,[2][3] or dough. If you continue browsing the site, you agree to the use of cookies on this website. By understanding the advantages and disadvantages of each type of media and abrasive flow machining styles the most cost effective results can be achieved. The AFM process provides process control that delivers consistent quality and high repeatability. 1. Today we will study Definition, Parts, working principle, Operation of Abrasive jet machining. Effects of Abrasive on Abrasive Jet Machining Performance, Desired Properties of Abrasives Used in Abrasive Jet Machining (AJM), Explain Working Principle of Abrasive Jet Machining with Sketch. These are the following applications of Abrasive Jet Machining: The advantages of Abrasive jet machine are: The disadvantages of Abrasive Jet Machining are: So this is all about Abrasive Jet MAchining Process, I hope you like it, feel free to mention your doubts on the comment section, I will love to answer those, till then see you, bye! However silicon carbide is a better choice for cutting harder materials due to the superior sharpness of silicon carbide. Your email address will not be published. In this new article, we will study Definition, Parts or Construction, Working Principle, Advantages, Disadvantages and Application of Honing Lapping Process: Definition, Working Principle, Types, Material, Advantages, Application [Notes with PDF]. Abrasive flow machining also easily allows operators to work in hard to reach areas and the overall process is much faster than other process that attempt to perform the same application. Abrasive jet machining (AJM) can be advantageously utilized for such purpose. Various advantages and disadvantages of abrasive jet machining (AJM) are elaborated in the successive sections. https://blog.iqsdirectory.com/abrasive-flow-machining/, Preventing Bond Failure in Rubber to Metal Bonding, Latest Insights in the Evolving Digital World. In fact, our Extrude Hone line of machining solutions can reach, shape and perfect surfaces you cant even see to provide improved performance you can measure. seal air milling flour machinery mill process grain scale list impact traditional steel Abrasive Jet Machining Parts or Construction: Working Principle of Abrasive Jet Machining: https://www.sciencedirect.com/topics/materials-science/abrasive-jet-machining, https://www.researchgate.net/publication/222641589_A_review_of_abrasive_jet_machining. I forget to say that, DONT FORGET SHARE IT ON YOUR FAVOURITE SOCIAL MEDIA PLATFORM AND BE A PART OF #SPREAD_THE_KNOWLEDGE. Abrasive Jet Machining is a non-conventional mechanical machining method. Stabilizes media viscosity throughout long process periods. Predictability. The abrasive and gas mixture comes out from the nozzle at a high velocity ranging from 150 to 300 meters/minute and impinges over the work surface causing abrasion action by repeated impacts and the material is removed by the erosion.

[1][3][2] This fluid is typically very viscous, having the consistency of putty,[2][3] or dough. If you continue browsing the site, you agree to the use of cookies on this website. By understanding the advantages and disadvantages of each type of media and abrasive flow machining styles the most cost effective results can be achieved. The AFM process provides process control that delivers consistent quality and high repeatability. 1. Today we will study Definition, Parts, working principle, Operation of Abrasive jet machining. Effects of Abrasive on Abrasive Jet Machining Performance, Desired Properties of Abrasives Used in Abrasive Jet Machining (AJM), Explain Working Principle of Abrasive Jet Machining with Sketch. These are the following applications of Abrasive Jet Machining: The advantages of Abrasive jet machine are: The disadvantages of Abrasive Jet Machining are: So this is all about Abrasive Jet MAchining Process, I hope you like it, feel free to mention your doubts on the comment section, I will love to answer those, till then see you, bye! However silicon carbide is a better choice for cutting harder materials due to the superior sharpness of silicon carbide. Your email address will not be published. In this new article, we will study Definition, Parts or Construction, Working Principle, Advantages, Disadvantages and Application of Honing Lapping Process: Definition, Working Principle, Types, Material, Advantages, Application [Notes with PDF]. Abrasive flow machining also easily allows operators to work in hard to reach areas and the overall process is much faster than other process that attempt to perform the same application. Abrasive jet machining (AJM) can be advantageously utilized for such purpose. Various advantages and disadvantages of abrasive jet machining (AJM) are elaborated in the successive sections. https://blog.iqsdirectory.com/abrasive-flow-machining/, Preventing Bond Failure in Rubber to Metal Bonding, Latest Insights in the Evolving Digital World. In fact, our Extrude Hone line of machining solutions can reach, shape and perfect surfaces you cant even see to provide improved performance you can measure. seal air milling flour machinery mill process grain scale list impact traditional steel Abrasive Jet Machining Parts or Construction: Working Principle of Abrasive Jet Machining: https://www.sciencedirect.com/topics/materials-science/abrasive-jet-machining, https://www.researchgate.net/publication/222641589_A_review_of_abrasive_jet_machining. I forget to say that, DONT FORGET SHARE IT ON YOUR FAVOURITE SOCIAL MEDIA PLATFORM AND BE A PART OF #SPREAD_THE_KNOWLEDGE. Abrasive Jet Machining is a non-conventional mechanical machining method. Stabilizes media viscosity throughout long process periods. Predictability. The abrasive and gas mixture comes out from the nozzle at a high velocity ranging from 150 to 300 meters/minute and impinges over the work surface causing abrasion action by repeated impacts and the material is removed by the erosion.  Abrasive collection and disposal are problematicTiny grains of abrasive are injurious to health and must not be allowed to mix with atmosphere after machining. The metal removal rate increases with an increase in nozzle tip distance up to a maximum value. Discover BVA, Extrude Hone agent in Turkey. This method facilitates to machine the complex holes and intricate cavities of harder materials of desired shape. The speed of processing media slug through the workpiece passage. Both workpiece roughing and finishing can be completed in a single pass. 119 Years of Service Between Four Young Men. Note: You can download whole articles PDF at the end of the articles. Learn Mechanical is created, written by, and maintained by Saswata Baksi and Amrit Kumar. Customizability. The filtered gas is supplied that is between the pressure limits of 1.96 bar to 7.85 bar to the mixing chamber that comprises abrasive powder. Process is independent of electrical or thermal propertiesElectrical or thermal conductivity of work material does not influence the abrasive jet machining capability. Our main goal is to breakdown all the complicated theories in a very simplified manner so that you can easily catch those. Polishing: Uniformly improving the surface finish while preserving the component geometry. Abrasive flow machining is a finishing process for a variety of materials including tough metals such as titanium. Whether your component finishing operation is as routine as surface polishing or burr removal or as complex as final shaping of slots, breakthroughs and drilled hole openings, our Abrasive Flow Machining / Extrude Honing (AFM) process will meet your needs. [1] The highest amount of material removal occurs in areas where the flow of the fluid is restricted; according to Bernoulli's Principle, the flow speed and pressure of the fluid increase in these areas, facilitating a higher material removal rate (MRR).

Abrasive collection and disposal are problematicTiny grains of abrasive are injurious to health and must not be allowed to mix with atmosphere after machining. The metal removal rate increases with an increase in nozzle tip distance up to a maximum value. Discover BVA, Extrude Hone agent in Turkey. This method facilitates to machine the complex holes and intricate cavities of harder materials of desired shape. The speed of processing media slug through the workpiece passage. Both workpiece roughing and finishing can be completed in a single pass. 119 Years of Service Between Four Young Men. Note: You can download whole articles PDF at the end of the articles. Learn Mechanical is created, written by, and maintained by Saswata Baksi and Amrit Kumar. Customizability. The filtered gas is supplied that is between the pressure limits of 1.96 bar to 7.85 bar to the mixing chamber that comprises abrasive powder. Process is independent of electrical or thermal propertiesElectrical or thermal conductivity of work material does not influence the abrasive jet machining capability. Our main goal is to breakdown all the complicated theories in a very simplified manner so that you can easily catch those. Polishing: Uniformly improving the surface finish while preserving the component geometry. Abrasive flow machining is a finishing process for a variety of materials including tough metals such as titanium. Whether your component finishing operation is as routine as surface polishing or burr removal or as complex as final shaping of slots, breakthroughs and drilled hole openings, our Abrasive Flow Machining / Extrude Honing (AFM) process will meet your needs. [1] The highest amount of material removal occurs in areas where the flow of the fluid is restricted; according to Bernoulli's Principle, the flow speed and pressure of the fluid increase in these areas, facilitating a higher material removal rate (MRR).  With AFM tooling, it is critical that the designed fixture appropriately manage the media pressure in the gap between the fixture and the part. It can also be applied for cutting and drilling operations. 6. 4 0 obj

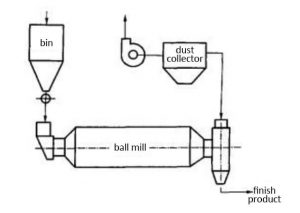

In industry sectors such as aerospace, automotive, energy, and medical, precision finishing of machined parts is critical to the refinement of end product performance levels. However, if the same is applied for cutting various shapes or drilling holes, the quality of cut may not be good because of jet flaring. The pressure form regulator is also employed to regulate the gas flow while the abrasive powder feed rate is regulated by amplitude of vibration of mixing chamber. Four types of abrasives commonly used include: aluminum oxide, silicon carbide, boron carbide and diamond. Filter indicates the cleanness of the fuel supply. bore Both will get a mix thats why this is called a Mixing chamber. machine flour damper sieve dust wheat mill plant pneumatic sifter The figure shown is the above Abrasive jet Machining. Larger grit size provides high surface roughness but high material removal rate (MRR). The material removal rate increases linearly with an increase in mass flow rate. Introduction to Pressure Vessels Vessels, tanks, and pipelines that carry, store, or receive fluids are called pressure vessels. <>

Blockchain + AI + Crypto Economics Are We Creating a Code Tsunami? Abrasive flow machining is divided into three categories: one way, two way and orbital. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This site uses Akismet to reduce spam. A list of pros and cons of AJM is also depicted below. definition advantages link to Pressure Vessels - Parts, Design, Application, Types, Material, Diagram, Abrasive Jet Machining Working, Advantages, Disadvantages and Applications, 3D Learn Mechanical Click here to Download From Play Store. The range of temperature of the media slug during the machining process. The abrasive gas mixture, jet pressure, abrasive particle size and hardness are mainly responsible for the metal removal rate. In this machining, the Abrasive particle size is 10-40 Micros. grinding stpetersnt The principle size ranges from 10 meters to 50. CHEMICAL AND ELECTRO-CHEMICAL ENERGY BASED PROCESS, National Institute of Technology, Hamirpur, national institute of foundry and forge technology, Matoshri Pratishthan's Vishwabharti Polytechnic Institute, Nanded, RECENT TRENDS IN NON-TRADITIONAL MACHINING PROCESSES, ABRASIVE JET MACHINING by Ms Shikha Kashyap, UCM - Unit 2 -thermal and electrical energy based processes. In many cases, the same batch of media can be used on different metals without transferring removed material between different workpieces. The AFM process can improve a components air, gas, or liquid flow behavior and reduce or eliminate cavitation tendency. Wide range of surface finish can be obtainedSurface roughness of 0.1 1.5 micron is achievable in AJM using various sizes of abrasives. The same type of media can be used on different metals.

With AFM tooling, it is critical that the designed fixture appropriately manage the media pressure in the gap between the fixture and the part. It can also be applied for cutting and drilling operations. 6. 4 0 obj

In industry sectors such as aerospace, automotive, energy, and medical, precision finishing of machined parts is critical to the refinement of end product performance levels. However, if the same is applied for cutting various shapes or drilling holes, the quality of cut may not be good because of jet flaring. The pressure form regulator is also employed to regulate the gas flow while the abrasive powder feed rate is regulated by amplitude of vibration of mixing chamber. Four types of abrasives commonly used include: aluminum oxide, silicon carbide, boron carbide and diamond. Filter indicates the cleanness of the fuel supply. bore Both will get a mix thats why this is called a Mixing chamber. machine flour damper sieve dust wheat mill plant pneumatic sifter The figure shown is the above Abrasive jet Machining. Larger grit size provides high surface roughness but high material removal rate (MRR). The material removal rate increases linearly with an increase in mass flow rate. Introduction to Pressure Vessels Vessels, tanks, and pipelines that carry, store, or receive fluids are called pressure vessels. <>