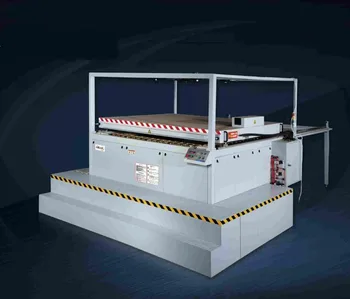

This is done either by lowering the sheet into the mold or by raising the mold into the sheet. : Heat Oven Is the temperature adjustable? >Manual Acrylic Bending Machine ABM700/1300, 365D(exclude force majeure,aritificial factors). Applicable sheet thickness: 1-10mm. We will never rent or sell your email to anyone. It is suggested using oven heating to make big arc. The parts can also be produced in different colors, with details and different designs. 2000-2017 Bel-o-Vac Industries | All rights reserved. When all these are done, the acrylic thermoformed products will be ready to integrate with their manufacturing processes. We offer, time proven, industry-tested vacuum and thermoforming technology. Forming width:3000mm(Customizable) Sometimes, there are dimensional inconsistencies which also results from improper temperature controlled tool design. Acrylic sheet molding process of vacuum forming is used to create numerous types of agricultural equipment. A: Normal plug has 4version, E.U plug, British plug, U.S plug, and C.N plug. It is used to bend acrylic to make triangle table signs. They are either vacuum or drape formed depending on the shape and aesthetic needs of a particular application. It happens when the parts are forming over the mold with inadequate venting in areas of geometry or aesthetic design. Failure to do this may result in blistering of the sheet during forming, thus compromising the quality of the product. The fact that high-quality acrylic plastic sheet is used means the acrylic thermoforming method is not cost effective.  The large vacuum forming machine is also equipped with a timer, it can set different heating times according to the thickness of materials and ambient temperature. multifunction abs Shandong Yuantong Century Intelligent Technology Co., Ltd. Machinery & Hardware, Food & Beverage, Medical, Toys, Commodity, Textiles, Chemical, Apparel. Thermoformed acrylic sheet produces good quality protective housing for consumer, business and medical displays. You can also add supplemental heat to the corners. The sheet should, therefore, be dried in a spare oven, and immediately be transferred into the forming oven at 80C. After setting the heating temperature, 12 high-power heating tubes can quickly soften the acrylic and plastics sheet. Whether you are for group or individual sourcing, we will provide you with the latest technology and the comprehensive data of Chinese suppliers like Acrylic Vacuum Forming Machine factory list to enhance your sourcing performance in the business line of manufacturing & processing machinery. Therefore, with this problem, it can be costly. They are affordable and dependable for consumer goods, medical components, and office equipment. This provides an opportunity to produce a wide variety of products that enables competition in the market. The formed sheet remains in the mold cavity for a few seconds as it cools down and thereafter, is ejected. machine bathtub forming vacuum thermoforming acrylic making larger 3mm thickness sheet need heating width at least 8mm. After setting the heating temperature, 12 high-power heating tubes can quickly soften the, can set different heating times according to the thickness, support 3 processing modes. Tooling set for thermoforming Photo courtesy: Research gate. This means that it can be used in low-level production providing an opportunity to produce small quantities economically. It has holes under and in the side of machine, helps to cooling and extending machine life. : Packing This vacuum molding machine is equipped with a temperature controller. This section covers some of the most common factors and procedures that affect the quality of acrylic thermoforming process. The three-phase power supply of the vacuum forming machine for sale is equipped with special indicator lights, its convenient for observing when the phase is missing. byt alina bsx depth 1200 thick larger Let us now have a close look at some of the basics in acrylic thermoforming. By so doing, you will raise your initial tooling investment thereby saving the production cost. This method is cheap compared to other acrylic forming methods. Its a flexible process that is ideal for small and medium productions, large and small in size parts.

The large vacuum forming machine is also equipped with a timer, it can set different heating times according to the thickness of materials and ambient temperature. multifunction abs Shandong Yuantong Century Intelligent Technology Co., Ltd. Machinery & Hardware, Food & Beverage, Medical, Toys, Commodity, Textiles, Chemical, Apparel. Thermoformed acrylic sheet produces good quality protective housing for consumer, business and medical displays. You can also add supplemental heat to the corners. The sheet should, therefore, be dried in a spare oven, and immediately be transferred into the forming oven at 80C. After setting the heating temperature, 12 high-power heating tubes can quickly soften the acrylic and plastics sheet. Whether you are for group or individual sourcing, we will provide you with the latest technology and the comprehensive data of Chinese suppliers like Acrylic Vacuum Forming Machine factory list to enhance your sourcing performance in the business line of manufacturing & processing machinery. Therefore, with this problem, it can be costly. They are affordable and dependable for consumer goods, medical components, and office equipment. This provides an opportunity to produce a wide variety of products that enables competition in the market. The formed sheet remains in the mold cavity for a few seconds as it cools down and thereafter, is ejected. machine bathtub forming vacuum thermoforming acrylic making larger 3mm thickness sheet need heating width at least 8mm. After setting the heating temperature, 12 high-power heating tubes can quickly soften the, can set different heating times according to the thickness, support 3 processing modes. Tooling set for thermoforming Photo courtesy: Research gate. This means that it can be used in low-level production providing an opportunity to produce small quantities economically. It has holes under and in the side of machine, helps to cooling and extending machine life. : Packing This vacuum molding machine is equipped with a temperature controller. This section covers some of the most common factors and procedures that affect the quality of acrylic thermoforming process. The three-phase power supply of the vacuum forming machine for sale is equipped with special indicator lights, its convenient for observing when the phase is missing. byt alina bsx depth 1200 thick larger Let us now have a close look at some of the basics in acrylic thermoforming. By so doing, you will raise your initial tooling investment thereby saving the production cost. This method is cheap compared to other acrylic forming methods. Its a flexible process that is ideal for small and medium productions, large and small in size parts.  2. Video-1https://www.youtube.com/embed/ZEiN44L2PFs, Video-2https://www.youtube.com/embed/h6qkP6-VB7M, Video-3https://www.youtube.com/embed/X7AUfK3ZYOM. You'll find a wide variety of vacuum formers such as acrylic vacuum forming machine at Al-abaabacomcoms as the site has all types of power distribution units that will suit your needs. Q: Does the machine have CE certification?

2. Video-1https://www.youtube.com/embed/ZEiN44L2PFs, Video-2https://www.youtube.com/embed/h6qkP6-VB7M, Video-3https://www.youtube.com/embed/X7AUfK3ZYOM. You'll find a wide variety of vacuum formers such as acrylic vacuum forming machine at Al-abaabacomcoms as the site has all types of power distribution units that will suit your needs. Q: Does the machine have CE certification?  There are many acrylic thermoforming techniques.

There are many acrylic thermoforming techniques.  Two voltages are available, 220V and 110V. Plastic bending machine is widely used in School technical courses, building model,decoration engineering, sign making, display case, market shelves, advertising light box, artware making, etc. 12. A: Yes, fans are installed. Sharp vertical corners which have minimum draught angles. Intellectual Property Protection

Two voltages are available, 220V and 110V. Plastic bending machine is widely used in School technical courses, building model,decoration engineering, sign making, display case, market shelves, advertising light box, artware making, etc. 12. A: Yes, fans are installed. Sharp vertical corners which have minimum draught angles. Intellectual Property Protection  This helps in approximating the depth of the mold more closely. To acheive better cooling effect, please exchange the water when you feel the water is heated by your hand or the water temperature is up to 50. Thick-gauge, on the other hand, uses 0 .120 inches to manufacture industrial products like refrigerator liners, plastic pallets, and enclosures. : Model A: No. This is also as a result of inadequate vacuum venting in tool design and manufacture. To minimize this stress, you should use moderate forming rate. : Driven Type To minimize this, the frame should be heated to temperature before clamping the sheet. | 7.

This helps in approximating the depth of the mold more closely. To acheive better cooling effect, please exchange the water when you feel the water is heated by your hand or the water temperature is up to 50. Thick-gauge, on the other hand, uses 0 .120 inches to manufacture industrial products like refrigerator liners, plastic pallets, and enclosures. : Model A: No. This is also as a result of inadequate vacuum venting in tool design and manufacture. To minimize this stress, you should use moderate forming rate. : Driven Type To minimize this, the frame should be heated to temperature before clamping the sheet. | 7.  an alternative to poorly-designed, over-built and over-priced equipment. PHONE JB, Founder & Senior Engineer - 4. It is compatible with numerous types of engineered thermoplastics. Also, pre-dry, pre-heat, and keep masking on the sheet until formed and use older materials first. When you contact us..

an alternative to poorly-designed, over-built and over-priced equipment. PHONE JB, Founder & Senior Engineer - 4. It is compatible with numerous types of engineered thermoplastics. Also, pre-dry, pre-heat, and keep masking on the sheet until formed and use older materials first. When you contact us..  A: Plastic plate like Acrylic, Plexiglas, PVC, PC,ABS, PP and so on etc.

A: Plastic plate like Acrylic, Plexiglas, PVC, PC,ABS, PP and so on etc.  Using a surge tank, quickly pull the air out from between the mold and the sheet. Below are some critical areas that should not miss when evaluating Acrylic Vacuum Forming Machine for purchase.

Using a surge tank, quickly pull the air out from between the mold and the sheet. Below are some critical areas that should not miss when evaluating Acrylic Vacuum Forming Machine for purchase.  In this guide, I will take you through the definition of thermoforming acrylic, thermoforming basics, its advantages, and disadvantages. The temperature of infrared tube is ajustable according to different thickness of plastic sheet and max temperature is 600. The angle formed by the baffle and the back of the machine allows the bended angle of each plastic sheet to be the same. For example, it can be used to process parts that are between 0.060 0.50 inches. Established in the year 2014, we Spectrum Sign Systems is one of the foremost companies involved in Exporting, wholesale trading and importing an extensive series of CNC Machines, Laser Engraving Machine, Laser Cutting Machine, Laser Tubes, CNC Controller, Metal Laser Marking Machine, PVC Vacuum Press Machine, Laser Controller, Die Making Machine, Cutting Plotter and many more. If you desire to modify tools and parts of acrylic, it is achievable quickly and this is also very economical. | Showroom It costs around 50% more as compared to other methods like injection molded parts. BV dual station vacuum formers offer hi production with dual tool set ups commonly used In order to provide the top range of products to patrons, our firm has allied expert vendors team who has years of practice of this area. Fully robotic 5 and 6-axis trimmers can be used to quickly cut both complex and precise shapes. forming vacuum acrylic machine distributors companies looking thermal plastic larger To understand how long an acrylic sheet should be heated, you have to determine this by running a test cycle.

In this guide, I will take you through the definition of thermoforming acrylic, thermoforming basics, its advantages, and disadvantages. The temperature of infrared tube is ajustable according to different thickness of plastic sheet and max temperature is 600. The angle formed by the baffle and the back of the machine allows the bended angle of each plastic sheet to be the same. For example, it can be used to process parts that are between 0.060 0.50 inches. Established in the year 2014, we Spectrum Sign Systems is one of the foremost companies involved in Exporting, wholesale trading and importing an extensive series of CNC Machines, Laser Engraving Machine, Laser Cutting Machine, Laser Tubes, CNC Controller, Metal Laser Marking Machine, PVC Vacuum Press Machine, Laser Controller, Die Making Machine, Cutting Plotter and many more. If you desire to modify tools and parts of acrylic, it is achievable quickly and this is also very economical. | Showroom It costs around 50% more as compared to other methods like injection molded parts. BV dual station vacuum formers offer hi production with dual tool set ups commonly used In order to provide the top range of products to patrons, our firm has allied expert vendors team who has years of practice of this area. Fully robotic 5 and 6-axis trimmers can be used to quickly cut both complex and precise shapes. forming vacuum acrylic machine distributors companies looking thermal plastic larger To understand how long an acrylic sheet should be heated, you have to determine this by running a test cycle.  : Forming Area According to different material and thickness of sheet, the gap width can be adjustable. It is used to bend acrylic for displaying products such as appliances, mobile phones, cosmetics, magazines, shoes, etc. Therefore, it is required that you find an approximate temperature by using a pyrometer calibrated for plastics. The current heating lamp could not achieve the requirement of stable quality and heating temperature. It is possible to form fine details such as surface texture on the mold without having to incur additional costs. A: Softening and bending of plastic plate by far Infrared heating, shaped by hand or any mould. Thank you. minimizing on labor cost. To avoid this mess, heat the acrylic sheet evenly and use heated frames.

: Forming Area According to different material and thickness of sheet, the gap width can be adjustable. It is used to bend acrylic for displaying products such as appliances, mobile phones, cosmetics, magazines, shoes, etc. Therefore, it is required that you find an approximate temperature by using a pyrometer calibrated for plastics. The current heating lamp could not achieve the requirement of stable quality and heating temperature. It is possible to form fine details such as surface texture on the mold without having to incur additional costs. A: Softening and bending of plastic plate by far Infrared heating, shaped by hand or any mould. Thank you. minimizing on labor cost. To avoid this mess, heat the acrylic sheet evenly and use heated frames.  A: Yes. Q: Whats the working theory of acrylic bending machine?

A: Yes. Q: Whats the working theory of acrylic bending machine?  All rights reserved. Tell us your exact application, like an advertising sign.billboard, bathtub.auto parts covers etc, In most cases, thermoforming acrylics are used for large products.

All rights reserved. Tell us your exact application, like an advertising sign.billboard, bathtub.auto parts covers etc, In most cases, thermoforming acrylics are used for large products.  Tmall Taobao World 20. Full auto high tech PLC controlled productionthermoformer. These include panels, roofs, interior components for tractors and farm machinery, sprayer shells, feed/water containers, and livestock housings. : Automation 1. - User Information Legal Enquiry Guide, 1999-2022 Alibaba.com. However, others have no such specifications. What is the price of Acrylic Vacuum Forming Machine? Regardless of the business,, wholesale buyers can find everything you need, with long prices and fast delivery from a range of manufacturers and suppliers. It is a faster process as compared to other manufacturing methods. 16. Adjustable heating gap:0-20mm. Bel-O-Vac Industries offers complete tooling services from conception to production. At times, parts have a poor surface finish and therefore have to be trimmed. forming vacuum acrylic bxy multifunction 1500 machine larger 1) Makingmolds , mold can be MDF or metal . It can also form very large parts and complex shapes at a cheaper cost. This feature can make the product more standardized and make manufacture more convenient. This is a versatile and reliable process for any number of applications. Q: Can I buy extra heating tubes for replacing? Some of the main advantages of acrylic thermoforming include: They are flexible and can be used to produce any desired shape and size. : Port You will be speaking with one of our knowledgeable design engineers that will take the time This is because once the design has been confirmed, thermoformed parts can be ready within a month or less. | Affiliate, Product Listing Policy Inconsistent Acrylic part thickness is another problem. completed many thousands of projects. quipped with a temperature controller. How to make the products? Finding the right product to integrate into the workflow should be an easy task. The remedy here is to use a female tool to prevent the webbing. Please inform us of your working material kind, (Max size and Material) or drawings.like acrylic, ABS, PLA, PMMA.PC etc. : After-sales Service Copyright 1996-2022 IndiaMART InterMESH Ltd. All rights reserved. : Type Nevertheless, the requirements for temperature depend on forming conditions like the degree of shaping/stretching and the forming rate. Manufacturing companies use CAD files. You can then place your order depending on the purpose for which the machine is intended and your budget. This can be caused by improper tooling materials selection or inadequate tool surface finishing. station where you will see one of the largest libaries of projects of our past Post sourcing requests and get quotations quickly. 4.Circulating water cooling system by submerged pump, keep the worktable stay in cool condition to protect hand and machine. There are those that are distinctly made to carry out pressure forming or vacuum ones. Pressure forming acrylic sheet can form pieces with vents and louvers. panels- industrial cases-shipping cases acrylic sky lights- Air plane This will result in a failure to produce the desired results. made of square steel, and the main fixture is made, controlled by 4 cylinders separately. It is limited to shape complexity and thin-walled parts. Video Clips | Through this process, they produce surroundings of computer screens, soft transparent keyboard covers, enclosures, and ancillary equipment. interiors commercial signs- truck linersRecommended plastic gauge 3/8"(.95cm) Stay updated to what's new and popular on the market. Raised corners as a result of excessive stress. Acrylic sheet develops stress when the forming rate is excessively fast, and this causes low craze resistance. | A: It is suggested to use big water tank or bucket. It is only ideal for applications that use shallow acrylic parts which are formed into cavities. (951) 741-4822 So many products can be created using vacuum forming, ad the limits are only defined by your creativity. : Product Type How do I choose Acrylic Vacuum Forming Machine? Onetouch A: Yes.Caution: To ensure the power supply is turned off, before cleaning and replairing. Thermoformable Anti Fog Anti Scratch Polycarbonate Sheet, Thermoforming Acrylic: The Ultimate Guide, 11 Great Technologies to Skyrocket Your Football Visor Business, Photochromic: Complete Guide Book to Learn Everything About Photochromic Technology. Including Type, Material, Function and so on. These machines exist in a variety of capacities with different price allocations. vacuum former this model offers heavy to light gauge high detailed vacuum forming Warranty : Processing Technics 8. thermoforming acrylic Advertising equipment,light box.acrylic singn.logo etc, 2.Decoration &redecoration ,furniture,bathtub.wallpaper etc. Acrylic has the ability to resist deformation, but when heated, it becomes elastic and begins to form over a mold.

Tmall Taobao World 20. Full auto high tech PLC controlled productionthermoformer. These include panels, roofs, interior components for tractors and farm machinery, sprayer shells, feed/water containers, and livestock housings. : Automation 1. - User Information Legal Enquiry Guide, 1999-2022 Alibaba.com. However, others have no such specifications. What is the price of Acrylic Vacuum Forming Machine? Regardless of the business,, wholesale buyers can find everything you need, with long prices and fast delivery from a range of manufacturers and suppliers. It is a faster process as compared to other manufacturing methods. 16. Adjustable heating gap:0-20mm. Bel-O-Vac Industries offers complete tooling services from conception to production. At times, parts have a poor surface finish and therefore have to be trimmed. forming vacuum acrylic bxy multifunction 1500 machine larger 1) Makingmolds , mold can be MDF or metal . It can also form very large parts and complex shapes at a cheaper cost. This feature can make the product more standardized and make manufacture more convenient. This is a versatile and reliable process for any number of applications. Q: Can I buy extra heating tubes for replacing? Some of the main advantages of acrylic thermoforming include: They are flexible and can be used to produce any desired shape and size. : Port You will be speaking with one of our knowledgeable design engineers that will take the time This is because once the design has been confirmed, thermoformed parts can be ready within a month or less. | Affiliate, Product Listing Policy Inconsistent Acrylic part thickness is another problem. completed many thousands of projects. quipped with a temperature controller. How to make the products? Finding the right product to integrate into the workflow should be an easy task. The remedy here is to use a female tool to prevent the webbing. Please inform us of your working material kind, (Max size and Material) or drawings.like acrylic, ABS, PLA, PMMA.PC etc. : After-sales Service Copyright 1996-2022 IndiaMART InterMESH Ltd. All rights reserved. : Type Nevertheless, the requirements for temperature depend on forming conditions like the degree of shaping/stretching and the forming rate. Manufacturing companies use CAD files. You can then place your order depending on the purpose for which the machine is intended and your budget. This can be caused by improper tooling materials selection or inadequate tool surface finishing. station where you will see one of the largest libaries of projects of our past Post sourcing requests and get quotations quickly. 4.Circulating water cooling system by submerged pump, keep the worktable stay in cool condition to protect hand and machine. There are those that are distinctly made to carry out pressure forming or vacuum ones. Pressure forming acrylic sheet can form pieces with vents and louvers. panels- industrial cases-shipping cases acrylic sky lights- Air plane This will result in a failure to produce the desired results. made of square steel, and the main fixture is made, controlled by 4 cylinders separately. It is limited to shape complexity and thin-walled parts. Video Clips | Through this process, they produce surroundings of computer screens, soft transparent keyboard covers, enclosures, and ancillary equipment. interiors commercial signs- truck linersRecommended plastic gauge 3/8"(.95cm) Stay updated to what's new and popular on the market. Raised corners as a result of excessive stress. Acrylic sheet develops stress when the forming rate is excessively fast, and this causes low craze resistance. | A: It is suggested to use big water tank or bucket. It is only ideal for applications that use shallow acrylic parts which are formed into cavities. (951) 741-4822 So many products can be created using vacuum forming, ad the limits are only defined by your creativity. : Product Type How do I choose Acrylic Vacuum Forming Machine? Onetouch A: Yes.Caution: To ensure the power supply is turned off, before cleaning and replairing. Thermoformable Anti Fog Anti Scratch Polycarbonate Sheet, Thermoforming Acrylic: The Ultimate Guide, 11 Great Technologies to Skyrocket Your Football Visor Business, Photochromic: Complete Guide Book to Learn Everything About Photochromic Technology. Including Type, Material, Function and so on. These machines exist in a variety of capacities with different price allocations. vacuum former this model offers heavy to light gauge high detailed vacuum forming Warranty : Processing Technics 8. thermoforming acrylic Advertising equipment,light box.acrylic singn.logo etc, 2.Decoration &redecoration ,furniture,bathtub.wallpaper etc. Acrylic has the ability to resist deformation, but when heated, it becomes elastic and begins to form over a mold.  A family that cares.. Acrylic, PP, PE, PMMA, PVC, PET, ABS.PA, etc. B2-20120091-4, advertising equipment vacuum forming machine, vacuum forming machine thermoforming china sale. Aeronautical manufacturers use this application to make interior trim panels, covers cowlings and internal sections for (NASA) space shuttle. In addition to this, you can also add supplemental heat to the corners. Machine Vaccum Forming Used Form Automatic Positive And Negative Pressure Machine Thermoming Vaccum Forming Machine, Vacuum Machine Thermoforming Vacuum Packaging Machine Date Food Tray Sealing PackIng Thermoforming Vacuum Packaging Machine, Acrylic Vaccum Machine Vacuum Forming Small Vacuum Forming Machine Hot Sell Small Acrylic Vaccum Molding Machine With Cheaper Price Vacuum Formers Forming Machine, Vaccum Machines Vacuum Forming Machine Leadworld Vaccum Packing Machines Kitchen Automatic Vacuum Food Sealer Packaging Forming Vakum Machine For Vaccum Packing, Vacuum Forming Machine Hot Selling Most Popular Dental Lab Vacuum Forming Machine Thermoforming Vacuum Forming Machine, Lightbox 3D Letters Acrylic sign vacuum thermo forming machine, Acrylic Letter 3D sign vacuum thermo forming machine for acrylic sheet molding, 1212 1224 2030 Acrylic Letters Plastic Vacuum Forming Machine for Signage, Small automatic plastic blister container tray vacuum forming machine for chicken quail eggs, 3D car mats Thick sheet vacuum forming machine, Small mini desktop tabletop acrylic pvc plastic vacuum former / thermo vacuum forming machine, Manual semi automatic blister packing seedling tray seeds plastic transparent thick acrylic sheet board vacuum forming machine, Acrylic vacuum forming machine thermoforming for advertising letters, 2020 New Acrylic ABS Plastic Vacuum Former Thermal Forming Machine for Advertising Signage 3D Letter Light Box, Plastic Blister Drawbar Box Vacuum Forming Machine, Mini size cheap price desktop manual acrylic thermo vacuum forming machine with CE, Fair Price Custom Automatic Thick Acrylic Sheet Bathtub Vacuum Forming Making Machine, Mechanical Equipment Blister Machine Packing Automatic Thermoforming Acrylic Vacuum Forming Machine Egg Tray Making Machines, Automatic Advertising Multifunctional Blow-Pressing Suction Acrylic Hydraulic Blister Vacuum Forming Machine, Stable Quality Acrylic ABS PVC thermoforming machine vacuum forming machine for advertising sign/billboard, Mini Desktop Plastic Small Vacuum forming machine for Acrylic, PVC, ABS ,PET etc, Perfect Laser - 3D Acrylic Signs Letters Plastic Wall Panel Multi functional Vacuum Forming Machine, Automatic Plastic Vacuum Forming Machine For Safety Helmet Construction For Sale, acrylic vacuum forming machine Used in the dining box hardware tool thermoforms blister packaging machine, Fast speed mini deep acrylic vacuum forming machine, Semi automatic acrylic bathtub vacuum forming machine thermoforming, Plastic thermoforming machine Acrylic vacuum forming machine, Support Custom Acrylic ABS Vacuum Thermoforming Former Machinery Mini Spa Vacuum Forming Machine, Hengrong ABS acrylic vacuum forming machine for advertising 3d sign logo decoration board making thermoforming, factory supply Acrylic letter vacuum forming machine/Acrylic shaping machine for sale, Direct Manufacturer Single Station Vacuum Forming Blister Acrylic Vacuum Forming Machine for Samples Making, Jing Yi Brand, Alibaba recommend abs vacuum forming machine, YESHINE fully automatic plastic abs pc vacuum carton tray forming machine, Automatic Plastic Acrylic Advertising Letter Making Vacuum Forming Machine. Recommended for the pre-heating and drying of heavy gauge and materials such as It is also determined by thermal conductivity. It produces products with beautiful gradual bends. : Material This feature can make the product more standardized and make manufacture more convenient. Web or unwanted wrinkles usually form around the mold particularly when you use the vacuum method of forming acrylic. Some units are specialized for the sign-making industry, while others lend themselves to art and craft projects like 3D poster creation. Like many manufacturing processes, thermoforming acrylic also has some problems which interfere with its successful process. The factors affecting the choice of material here include functional reasons like fire-related and high heat materials. 17. This application is very relevant here because acrylic can be exposed to UV radiation and elements. 1688.com Naturally, boxes aren't the only use for a acrylic vacuum forming machine. Vacuum forming acrylic sheet technique has the ability to form very large parts. Q: The water temperature will be heated after long time work. A: Yes. Q: There is white foam under heating lamp. we would encourage you, our new customer to review this site and take time to visit our YouTube Finding the right product to integrate into the workflow should be an easy task. vaco formacin caseras termoformadoras formech acrlico mquinas profundidad forming vacuum machine acrylic plastic larger The industry has found this application relevant because they use it to process chocolate molds for special occasions. Sometimes, techniques like power drape forming are used. Table sign is widely used in conference, hotel front desk agent, buffet. Modular engineered post and beam vacuum forming machine series, Supporting all the same equipment capabilities and features expected from a Belovac Belovac has been a family owned and operated company since 1984, and for over three decades we have successfully 6. Because the final product cools against the mold surface under ambient temperature, its finished parts have zero residual stress. This is one of the earliest thermoforming processes dating back to early Egyptian times. It saves up to about 90% of tooling cost as compared to other molding types. forming vacuum thermoforming Subscribe free newsletter to get latest products and discount information. This system offers split second timing and heat control for consistent product Copyright 2005-2022 YN. During drape forming, acrylic sheet is not typically stretched. PVC / Pet / PP / PS/ABS/EVA Automatic Plastic Blister, Cheap PVC PE Pet PC PS PP PMMA HIPS ABS Plastic Sheet Extrusion, Vacuum Oil Purification Machine Manufacturers, Vacuum Distillation Machine Manufacturers. It is small and portable machine, so it can be used in anywhere. acrylics, polycarbonates, and ABS. The single suction mode only needs to customize the male-mold, and the processed corners are rounded; the single pressure mode and the simultaneous pressure suction mode need to customize the female-mold and male-mold at the same time, and makes the characters more vividly. Roll Fed | forming vacuum pmma acrylic thermoforming machine pvc larger 1.Size: 700mm and 1300mm. We offer one standby heating tube for each ABM. Also, the parts that have sharp bends and corners are very difficult to produce. For instance, when the acrylic volume is larger, thermal conductivity is small and therefore the heating time becomes long. Only two models at present.ABM700: applicable length650mmABM1300: applicable length1250mm. In this case, you should add draught angle corners to allow the materials to flow over the mold or pattern. 5.Big worktable ensures evenly heated, no foaming, no deformation, easy to handle. Place the acrylic sheet on the mold surface and fixed using a clamping unit.

A family that cares.. Acrylic, PP, PE, PMMA, PVC, PET, ABS.PA, etc. B2-20120091-4, advertising equipment vacuum forming machine, vacuum forming machine thermoforming china sale. Aeronautical manufacturers use this application to make interior trim panels, covers cowlings and internal sections for (NASA) space shuttle. In addition to this, you can also add supplemental heat to the corners. Machine Vaccum Forming Used Form Automatic Positive And Negative Pressure Machine Thermoming Vaccum Forming Machine, Vacuum Machine Thermoforming Vacuum Packaging Machine Date Food Tray Sealing PackIng Thermoforming Vacuum Packaging Machine, Acrylic Vaccum Machine Vacuum Forming Small Vacuum Forming Machine Hot Sell Small Acrylic Vaccum Molding Machine With Cheaper Price Vacuum Formers Forming Machine, Vaccum Machines Vacuum Forming Machine Leadworld Vaccum Packing Machines Kitchen Automatic Vacuum Food Sealer Packaging Forming Vakum Machine For Vaccum Packing, Vacuum Forming Machine Hot Selling Most Popular Dental Lab Vacuum Forming Machine Thermoforming Vacuum Forming Machine, Lightbox 3D Letters Acrylic sign vacuum thermo forming machine, Acrylic Letter 3D sign vacuum thermo forming machine for acrylic sheet molding, 1212 1224 2030 Acrylic Letters Plastic Vacuum Forming Machine for Signage, Small automatic plastic blister container tray vacuum forming machine for chicken quail eggs, 3D car mats Thick sheet vacuum forming machine, Small mini desktop tabletop acrylic pvc plastic vacuum former / thermo vacuum forming machine, Manual semi automatic blister packing seedling tray seeds plastic transparent thick acrylic sheet board vacuum forming machine, Acrylic vacuum forming machine thermoforming for advertising letters, 2020 New Acrylic ABS Plastic Vacuum Former Thermal Forming Machine for Advertising Signage 3D Letter Light Box, Plastic Blister Drawbar Box Vacuum Forming Machine, Mini size cheap price desktop manual acrylic thermo vacuum forming machine with CE, Fair Price Custom Automatic Thick Acrylic Sheet Bathtub Vacuum Forming Making Machine, Mechanical Equipment Blister Machine Packing Automatic Thermoforming Acrylic Vacuum Forming Machine Egg Tray Making Machines, Automatic Advertising Multifunctional Blow-Pressing Suction Acrylic Hydraulic Blister Vacuum Forming Machine, Stable Quality Acrylic ABS PVC thermoforming machine vacuum forming machine for advertising sign/billboard, Mini Desktop Plastic Small Vacuum forming machine for Acrylic, PVC, ABS ,PET etc, Perfect Laser - 3D Acrylic Signs Letters Plastic Wall Panel Multi functional Vacuum Forming Machine, Automatic Plastic Vacuum Forming Machine For Safety Helmet Construction For Sale, acrylic vacuum forming machine Used in the dining box hardware tool thermoforms blister packaging machine, Fast speed mini deep acrylic vacuum forming machine, Semi automatic acrylic bathtub vacuum forming machine thermoforming, Plastic thermoforming machine Acrylic vacuum forming machine, Support Custom Acrylic ABS Vacuum Thermoforming Former Machinery Mini Spa Vacuum Forming Machine, Hengrong ABS acrylic vacuum forming machine for advertising 3d sign logo decoration board making thermoforming, factory supply Acrylic letter vacuum forming machine/Acrylic shaping machine for sale, Direct Manufacturer Single Station Vacuum Forming Blister Acrylic Vacuum Forming Machine for Samples Making, Jing Yi Brand, Alibaba recommend abs vacuum forming machine, YESHINE fully automatic plastic abs pc vacuum carton tray forming machine, Automatic Plastic Acrylic Advertising Letter Making Vacuum Forming Machine. Recommended for the pre-heating and drying of heavy gauge and materials such as It is also determined by thermal conductivity. It produces products with beautiful gradual bends. : Material This feature can make the product more standardized and make manufacture more convenient. Web or unwanted wrinkles usually form around the mold particularly when you use the vacuum method of forming acrylic. Some units are specialized for the sign-making industry, while others lend themselves to art and craft projects like 3D poster creation. Like many manufacturing processes, thermoforming acrylic also has some problems which interfere with its successful process. The factors affecting the choice of material here include functional reasons like fire-related and high heat materials. 17. This application is very relevant here because acrylic can be exposed to UV radiation and elements. 1688.com Naturally, boxes aren't the only use for a acrylic vacuum forming machine. Vacuum forming acrylic sheet technique has the ability to form very large parts. Q: The water temperature will be heated after long time work. A: Yes. Q: There is white foam under heating lamp. we would encourage you, our new customer to review this site and take time to visit our YouTube Finding the right product to integrate into the workflow should be an easy task. vaco formacin caseras termoformadoras formech acrlico mquinas profundidad forming vacuum machine acrylic plastic larger The industry has found this application relevant because they use it to process chocolate molds for special occasions. Sometimes, techniques like power drape forming are used. Table sign is widely used in conference, hotel front desk agent, buffet. Modular engineered post and beam vacuum forming machine series, Supporting all the same equipment capabilities and features expected from a Belovac Belovac has been a family owned and operated company since 1984, and for over three decades we have successfully 6. Because the final product cools against the mold surface under ambient temperature, its finished parts have zero residual stress. This is one of the earliest thermoforming processes dating back to early Egyptian times. It saves up to about 90% of tooling cost as compared to other molding types. forming vacuum thermoforming Subscribe free newsletter to get latest products and discount information. This system offers split second timing and heat control for consistent product Copyright 2005-2022 YN. During drape forming, acrylic sheet is not typically stretched. PVC / Pet / PP / PS/ABS/EVA Automatic Plastic Blister, Cheap PVC PE Pet PC PS PP PMMA HIPS ABS Plastic Sheet Extrusion, Vacuum Oil Purification Machine Manufacturers, Vacuum Distillation Machine Manufacturers. It is small and portable machine, so it can be used in anywhere. acrylics, polycarbonates, and ABS. The single suction mode only needs to customize the male-mold, and the processed corners are rounded; the single pressure mode and the simultaneous pressure suction mode need to customize the female-mold and male-mold at the same time, and makes the characters more vividly. Roll Fed | forming vacuum pmma acrylic thermoforming machine pvc larger 1.Size: 700mm and 1300mm. We offer one standby heating tube for each ABM. Also, the parts that have sharp bends and corners are very difficult to produce. For instance, when the acrylic volume is larger, thermal conductivity is small and therefore the heating time becomes long. Only two models at present.ABM700: applicable length650mmABM1300: applicable length1250mm. In this case, you should add draught angle corners to allow the materials to flow over the mold or pattern. 5.Big worktable ensures evenly heated, no foaming, no deformation, easy to handle. Place the acrylic sheet on the mold surface and fixed using a clamping unit.  Thermoformed acrylic has a flexible ordering with short lead times of about four to six weeks. plastic components. It is difficult to mold ribs and bosses and very thick acrylic sheets cannot be formed. Suppliers with verified business licenses, From payment to delivery, we guarantee your trading security without charges, Suppliers reviewed by inspection services. They are always the outer protective covering of equipment. | Suppliers with similar tools were cycle timing is the same, or were two different tool set ups are Vacuum forming has restrictions. The use of high-quality sheets makes this method expensive to around 50% more than the use of other techniques. 8mm thickness sheet need 20mm heating width. We will provide This will help you to get better results. Using unheated frame can lead to tearing, edge distortion and formation of asymmetric shapes that were not intended. : Screw No. Apart from these, we will also journey through common problems in thermoforming acrylic, machine buying and the applications. The parameters for thin-gauge tooling include maximum mold size of up to 30 inches wide. It is used to manufacture products that require gradual curves or bends like windshields, machine guards and POP displays. Lazada, Browse Alphabetically: years of designing and developing the most reliable vacuum forming machine in the industry, Vacuum forming is very ideal for the larger and shorter-run components like bumpers and interior panels. If indeed has other demand, pls send exact picture to sales for further confirmation. The single suction mode only needs to customize the, , and the processed corners are rounded; the single pressure mode and the simultaneous pressure suction mode need to customize the, is equipped with 3 suction holes. This helps in reducing the tooling cost, material cost and production time. If we could buy from Chinese market, we could change as your demand. The Vacuum forming molding machine is used to make 2-3mm acrylic into flat, curved, and spherical characters, fonts, and light boxes. Vacuum forming could be exactly what you need. The sheet part that touches the mold first will cool and then cease to stretch. : Control Method User could use water tank or bucket with capacity 20L. It is used to bend plastic to make simple laboratory equipment. Contact | B-302, 3rd Floor, RG City Centre, Opposite Paharganj Police Station Motia Khan New Delhi - 110055, India, B-302, 3rd Floor, RG City Centre, Opposite Paharganj Police Station. Normally, it is faster to market with quick prototypes. It allows for the forming of products with sharper details, texture, different colors and undercuts.

Thermoformed acrylic has a flexible ordering with short lead times of about four to six weeks. plastic components. It is difficult to mold ribs and bosses and very thick acrylic sheets cannot be formed. Suppliers with verified business licenses, From payment to delivery, we guarantee your trading security without charges, Suppliers reviewed by inspection services. They are always the outer protective covering of equipment. | Suppliers with similar tools were cycle timing is the same, or were two different tool set ups are Vacuum forming has restrictions. The use of high-quality sheets makes this method expensive to around 50% more than the use of other techniques. 8mm thickness sheet need 20mm heating width. We will provide This will help you to get better results. Using unheated frame can lead to tearing, edge distortion and formation of asymmetric shapes that were not intended. : Screw No. Apart from these, we will also journey through common problems in thermoforming acrylic, machine buying and the applications. The parameters for thin-gauge tooling include maximum mold size of up to 30 inches wide. It is used to manufacture products that require gradual curves or bends like windshields, machine guards and POP displays. Lazada, Browse Alphabetically: years of designing and developing the most reliable vacuum forming machine in the industry, Vacuum forming is very ideal for the larger and shorter-run components like bumpers and interior panels. If indeed has other demand, pls send exact picture to sales for further confirmation. The single suction mode only needs to customize the, , and the processed corners are rounded; the single pressure mode and the simultaneous pressure suction mode need to customize the, is equipped with 3 suction holes. This helps in reducing the tooling cost, material cost and production time. If we could buy from Chinese market, we could change as your demand. The Vacuum forming molding machine is used to make 2-3mm acrylic into flat, curved, and spherical characters, fonts, and light boxes. Vacuum forming could be exactly what you need. The sheet part that touches the mold first will cool and then cease to stretch. : Control Method User could use water tank or bucket with capacity 20L. It is used to bend plastic to make simple laboratory equipment. Contact | B-302, 3rd Floor, RG City Centre, Opposite Paharganj Police Station Motia Khan New Delhi - 110055, India, B-302, 3rd Floor, RG City Centre, Opposite Paharganj Police Station. Normally, it is faster to market with quick prototypes. It allows for the forming of products with sharper details, texture, different colors and undercuts.

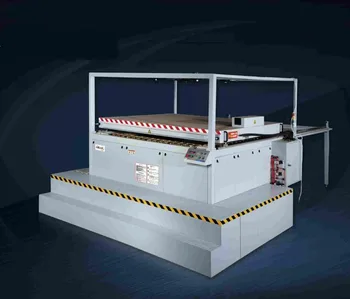

The large vacuum forming machine is also equipped with a timer, it can set different heating times according to the thickness of materials and ambient temperature. multifunction abs Shandong Yuantong Century Intelligent Technology Co., Ltd. Machinery & Hardware, Food & Beverage, Medical, Toys, Commodity, Textiles, Chemical, Apparel. Thermoformed acrylic sheet produces good quality protective housing for consumer, business and medical displays. You can also add supplemental heat to the corners. The sheet should, therefore, be dried in a spare oven, and immediately be transferred into the forming oven at 80C. After setting the heating temperature, 12 high-power heating tubes can quickly soften the acrylic and plastics sheet. Whether you are for group or individual sourcing, we will provide you with the latest technology and the comprehensive data of Chinese suppliers like Acrylic Vacuum Forming Machine factory list to enhance your sourcing performance in the business line of manufacturing & processing machinery. Therefore, with this problem, it can be costly. They are affordable and dependable for consumer goods, medical components, and office equipment. This provides an opportunity to produce a wide variety of products that enables competition in the market. The formed sheet remains in the mold cavity for a few seconds as it cools down and thereafter, is ejected. machine bathtub forming vacuum thermoforming acrylic making larger 3mm thickness sheet need heating width at least 8mm. After setting the heating temperature, 12 high-power heating tubes can quickly soften the, can set different heating times according to the thickness, support 3 processing modes. Tooling set for thermoforming Photo courtesy: Research gate. This means that it can be used in low-level production providing an opportunity to produce small quantities economically. It has holes under and in the side of machine, helps to cooling and extending machine life. : Packing This vacuum molding machine is equipped with a temperature controller. This section covers some of the most common factors and procedures that affect the quality of acrylic thermoforming process. The three-phase power supply of the vacuum forming machine for sale is equipped with special indicator lights, its convenient for observing when the phase is missing. byt alina bsx depth 1200 thick larger Let us now have a close look at some of the basics in acrylic thermoforming. By so doing, you will raise your initial tooling investment thereby saving the production cost. This method is cheap compared to other acrylic forming methods. Its a flexible process that is ideal for small and medium productions, large and small in size parts.

The large vacuum forming machine is also equipped with a timer, it can set different heating times according to the thickness of materials and ambient temperature. multifunction abs Shandong Yuantong Century Intelligent Technology Co., Ltd. Machinery & Hardware, Food & Beverage, Medical, Toys, Commodity, Textiles, Chemical, Apparel. Thermoformed acrylic sheet produces good quality protective housing for consumer, business and medical displays. You can also add supplemental heat to the corners. The sheet should, therefore, be dried in a spare oven, and immediately be transferred into the forming oven at 80C. After setting the heating temperature, 12 high-power heating tubes can quickly soften the acrylic and plastics sheet. Whether you are for group or individual sourcing, we will provide you with the latest technology and the comprehensive data of Chinese suppliers like Acrylic Vacuum Forming Machine factory list to enhance your sourcing performance in the business line of manufacturing & processing machinery. Therefore, with this problem, it can be costly. They are affordable and dependable for consumer goods, medical components, and office equipment. This provides an opportunity to produce a wide variety of products that enables competition in the market. The formed sheet remains in the mold cavity for a few seconds as it cools down and thereafter, is ejected. machine bathtub forming vacuum thermoforming acrylic making larger 3mm thickness sheet need heating width at least 8mm. After setting the heating temperature, 12 high-power heating tubes can quickly soften the, can set different heating times according to the thickness, support 3 processing modes. Tooling set for thermoforming Photo courtesy: Research gate. This means that it can be used in low-level production providing an opportunity to produce small quantities economically. It has holes under and in the side of machine, helps to cooling and extending machine life. : Packing This vacuum molding machine is equipped with a temperature controller. This section covers some of the most common factors and procedures that affect the quality of acrylic thermoforming process. The three-phase power supply of the vacuum forming machine for sale is equipped with special indicator lights, its convenient for observing when the phase is missing. byt alina bsx depth 1200 thick larger Let us now have a close look at some of the basics in acrylic thermoforming. By so doing, you will raise your initial tooling investment thereby saving the production cost. This method is cheap compared to other acrylic forming methods. Its a flexible process that is ideal for small and medium productions, large and small in size parts.  2. Video-1https://www.youtube.com/embed/ZEiN44L2PFs, Video-2https://www.youtube.com/embed/h6qkP6-VB7M, Video-3https://www.youtube.com/embed/X7AUfK3ZYOM. You'll find a wide variety of vacuum formers such as acrylic vacuum forming machine at Al-abaabacomcoms as the site has all types of power distribution units that will suit your needs. Q: Does the machine have CE certification?

2. Video-1https://www.youtube.com/embed/ZEiN44L2PFs, Video-2https://www.youtube.com/embed/h6qkP6-VB7M, Video-3https://www.youtube.com/embed/X7AUfK3ZYOM. You'll find a wide variety of vacuum formers such as acrylic vacuum forming machine at Al-abaabacomcoms as the site has all types of power distribution units that will suit your needs. Q: Does the machine have CE certification?  There are many acrylic thermoforming techniques.

There are many acrylic thermoforming techniques.  Two voltages are available, 220V and 110V. Plastic bending machine is widely used in School technical courses, building model,decoration engineering, sign making, display case, market shelves, advertising light box, artware making, etc. 12. A: Yes, fans are installed. Sharp vertical corners which have minimum draught angles. Intellectual Property Protection

Two voltages are available, 220V and 110V. Plastic bending machine is widely used in School technical courses, building model,decoration engineering, sign making, display case, market shelves, advertising light box, artware making, etc. 12. A: Yes, fans are installed. Sharp vertical corners which have minimum draught angles. Intellectual Property Protection  This helps in approximating the depth of the mold more closely. To acheive better cooling effect, please exchange the water when you feel the water is heated by your hand or the water temperature is up to 50. Thick-gauge, on the other hand, uses 0 .120 inches to manufacture industrial products like refrigerator liners, plastic pallets, and enclosures. : Model A: No. This is also as a result of inadequate vacuum venting in tool design and manufacture. To minimize this stress, you should use moderate forming rate. : Driven Type To minimize this, the frame should be heated to temperature before clamping the sheet. | 7.

This helps in approximating the depth of the mold more closely. To acheive better cooling effect, please exchange the water when you feel the water is heated by your hand or the water temperature is up to 50. Thick-gauge, on the other hand, uses 0 .120 inches to manufacture industrial products like refrigerator liners, plastic pallets, and enclosures. : Model A: No. This is also as a result of inadequate vacuum venting in tool design and manufacture. To minimize this stress, you should use moderate forming rate. : Driven Type To minimize this, the frame should be heated to temperature before clamping the sheet. | 7.  an alternative to poorly-designed, over-built and over-priced equipment. PHONE JB, Founder & Senior Engineer - 4. It is compatible with numerous types of engineered thermoplastics. Also, pre-dry, pre-heat, and keep masking on the sheet until formed and use older materials first. When you contact us..

an alternative to poorly-designed, over-built and over-priced equipment. PHONE JB, Founder & Senior Engineer - 4. It is compatible with numerous types of engineered thermoplastics. Also, pre-dry, pre-heat, and keep masking on the sheet until formed and use older materials first. When you contact us..  A: Plastic plate like Acrylic, Plexiglas, PVC, PC,ABS, PP and so on etc.

A: Plastic plate like Acrylic, Plexiglas, PVC, PC,ABS, PP and so on etc.  Using a surge tank, quickly pull the air out from between the mold and the sheet. Below are some critical areas that should not miss when evaluating Acrylic Vacuum Forming Machine for purchase.

Using a surge tank, quickly pull the air out from between the mold and the sheet. Below are some critical areas that should not miss when evaluating Acrylic Vacuum Forming Machine for purchase.  In this guide, I will take you through the definition of thermoforming acrylic, thermoforming basics, its advantages, and disadvantages. The temperature of infrared tube is ajustable according to different thickness of plastic sheet and max temperature is 600. The angle formed by the baffle and the back of the machine allows the bended angle of each plastic sheet to be the same. For example, it can be used to process parts that are between 0.060 0.50 inches. Established in the year 2014, we Spectrum Sign Systems is one of the foremost companies involved in Exporting, wholesale trading and importing an extensive series of CNC Machines, Laser Engraving Machine, Laser Cutting Machine, Laser Tubes, CNC Controller, Metal Laser Marking Machine, PVC Vacuum Press Machine, Laser Controller, Die Making Machine, Cutting Plotter and many more. If you desire to modify tools and parts of acrylic, it is achievable quickly and this is also very economical. | Showroom It costs around 50% more as compared to other methods like injection molded parts. BV dual station vacuum formers offer hi production with dual tool set ups commonly used In order to provide the top range of products to patrons, our firm has allied expert vendors team who has years of practice of this area. Fully robotic 5 and 6-axis trimmers can be used to quickly cut both complex and precise shapes. forming vacuum acrylic machine distributors companies looking thermal plastic larger To understand how long an acrylic sheet should be heated, you have to determine this by running a test cycle.

In this guide, I will take you through the definition of thermoforming acrylic, thermoforming basics, its advantages, and disadvantages. The temperature of infrared tube is ajustable according to different thickness of plastic sheet and max temperature is 600. The angle formed by the baffle and the back of the machine allows the bended angle of each plastic sheet to be the same. For example, it can be used to process parts that are between 0.060 0.50 inches. Established in the year 2014, we Spectrum Sign Systems is one of the foremost companies involved in Exporting, wholesale trading and importing an extensive series of CNC Machines, Laser Engraving Machine, Laser Cutting Machine, Laser Tubes, CNC Controller, Metal Laser Marking Machine, PVC Vacuum Press Machine, Laser Controller, Die Making Machine, Cutting Plotter and many more. If you desire to modify tools and parts of acrylic, it is achievable quickly and this is also very economical. | Showroom It costs around 50% more as compared to other methods like injection molded parts. BV dual station vacuum formers offer hi production with dual tool set ups commonly used In order to provide the top range of products to patrons, our firm has allied expert vendors team who has years of practice of this area. Fully robotic 5 and 6-axis trimmers can be used to quickly cut both complex and precise shapes. forming vacuum acrylic machine distributors companies looking thermal plastic larger To understand how long an acrylic sheet should be heated, you have to determine this by running a test cycle.  : Forming Area According to different material and thickness of sheet, the gap width can be adjustable. It is used to bend acrylic for displaying products such as appliances, mobile phones, cosmetics, magazines, shoes, etc. Therefore, it is required that you find an approximate temperature by using a pyrometer calibrated for plastics. The current heating lamp could not achieve the requirement of stable quality and heating temperature. It is possible to form fine details such as surface texture on the mold without having to incur additional costs. A: Softening and bending of plastic plate by far Infrared heating, shaped by hand or any mould. Thank you. minimizing on labor cost. To avoid this mess, heat the acrylic sheet evenly and use heated frames.

: Forming Area According to different material and thickness of sheet, the gap width can be adjustable. It is used to bend acrylic for displaying products such as appliances, mobile phones, cosmetics, magazines, shoes, etc. Therefore, it is required that you find an approximate temperature by using a pyrometer calibrated for plastics. The current heating lamp could not achieve the requirement of stable quality and heating temperature. It is possible to form fine details such as surface texture on the mold without having to incur additional costs. A: Softening and bending of plastic plate by far Infrared heating, shaped by hand or any mould. Thank you. minimizing on labor cost. To avoid this mess, heat the acrylic sheet evenly and use heated frames.  A: Yes. Q: Whats the working theory of acrylic bending machine?

A: Yes. Q: Whats the working theory of acrylic bending machine?  All rights reserved. Tell us your exact application, like an advertising sign.billboard, bathtub.auto parts covers etc, In most cases, thermoforming acrylics are used for large products.

All rights reserved. Tell us your exact application, like an advertising sign.billboard, bathtub.auto parts covers etc, In most cases, thermoforming acrylics are used for large products.  Tmall Taobao World 20. Full auto high tech PLC controlled productionthermoformer. These include panels, roofs, interior components for tractors and farm machinery, sprayer shells, feed/water containers, and livestock housings. : Automation 1. - User Information Legal Enquiry Guide, 1999-2022 Alibaba.com. However, others have no such specifications. What is the price of Acrylic Vacuum Forming Machine? Regardless of the business,, wholesale buyers can find everything you need, with long prices and fast delivery from a range of manufacturers and suppliers. It is a faster process as compared to other manufacturing methods. 16. Adjustable heating gap:0-20mm. Bel-O-Vac Industries offers complete tooling services from conception to production. At times, parts have a poor surface finish and therefore have to be trimmed. forming vacuum acrylic bxy multifunction 1500 machine larger 1) Makingmolds , mold can be MDF or metal . It can also form very large parts and complex shapes at a cheaper cost. This feature can make the product more standardized and make manufacture more convenient. This is a versatile and reliable process for any number of applications. Q: Can I buy extra heating tubes for replacing? Some of the main advantages of acrylic thermoforming include: They are flexible and can be used to produce any desired shape and size. : Port You will be speaking with one of our knowledgeable design engineers that will take the time This is because once the design has been confirmed, thermoformed parts can be ready within a month or less. | Affiliate, Product Listing Policy Inconsistent Acrylic part thickness is another problem. completed many thousands of projects. quipped with a temperature controller. How to make the products? Finding the right product to integrate into the workflow should be an easy task. The remedy here is to use a female tool to prevent the webbing. Please inform us of your working material kind, (Max size and Material) or drawings.like acrylic, ABS, PLA, PMMA.PC etc. : After-sales Service Copyright 1996-2022 IndiaMART InterMESH Ltd. All rights reserved. : Type Nevertheless, the requirements for temperature depend on forming conditions like the degree of shaping/stretching and the forming rate. Manufacturing companies use CAD files. You can then place your order depending on the purpose for which the machine is intended and your budget. This can be caused by improper tooling materials selection or inadequate tool surface finishing. station where you will see one of the largest libaries of projects of our past Post sourcing requests and get quotations quickly. 4.Circulating water cooling system by submerged pump, keep the worktable stay in cool condition to protect hand and machine. There are those that are distinctly made to carry out pressure forming or vacuum ones. Pressure forming acrylic sheet can form pieces with vents and louvers. panels- industrial cases-shipping cases acrylic sky lights- Air plane This will result in a failure to produce the desired results. made of square steel, and the main fixture is made, controlled by 4 cylinders separately. It is limited to shape complexity and thin-walled parts. Video Clips | Through this process, they produce surroundings of computer screens, soft transparent keyboard covers, enclosures, and ancillary equipment. interiors commercial signs- truck linersRecommended plastic gauge 3/8"(.95cm) Stay updated to what's new and popular on the market. Raised corners as a result of excessive stress. Acrylic sheet develops stress when the forming rate is excessively fast, and this causes low craze resistance. | A: It is suggested to use big water tank or bucket. It is only ideal for applications that use shallow acrylic parts which are formed into cavities. (951) 741-4822 So many products can be created using vacuum forming, ad the limits are only defined by your creativity. : Product Type How do I choose Acrylic Vacuum Forming Machine? Onetouch A: Yes.Caution: To ensure the power supply is turned off, before cleaning and replairing. Thermoformable Anti Fog Anti Scratch Polycarbonate Sheet, Thermoforming Acrylic: The Ultimate Guide, 11 Great Technologies to Skyrocket Your Football Visor Business, Photochromic: Complete Guide Book to Learn Everything About Photochromic Technology. Including Type, Material, Function and so on. These machines exist in a variety of capacities with different price allocations. vacuum former this model offers heavy to light gauge high detailed vacuum forming Warranty : Processing Technics 8. thermoforming acrylic Advertising equipment,light box.acrylic singn.logo etc, 2.Decoration &redecoration ,furniture,bathtub.wallpaper etc. Acrylic has the ability to resist deformation, but when heated, it becomes elastic and begins to form over a mold.

Tmall Taobao World 20. Full auto high tech PLC controlled productionthermoformer. These include panels, roofs, interior components for tractors and farm machinery, sprayer shells, feed/water containers, and livestock housings. : Automation 1. - User Information Legal Enquiry Guide, 1999-2022 Alibaba.com. However, others have no such specifications. What is the price of Acrylic Vacuum Forming Machine? Regardless of the business,, wholesale buyers can find everything you need, with long prices and fast delivery from a range of manufacturers and suppliers. It is a faster process as compared to other manufacturing methods. 16. Adjustable heating gap:0-20mm. Bel-O-Vac Industries offers complete tooling services from conception to production. At times, parts have a poor surface finish and therefore have to be trimmed. forming vacuum acrylic bxy multifunction 1500 machine larger 1) Makingmolds , mold can be MDF or metal . It can also form very large parts and complex shapes at a cheaper cost. This feature can make the product more standardized and make manufacture more convenient. This is a versatile and reliable process for any number of applications. Q: Can I buy extra heating tubes for replacing? Some of the main advantages of acrylic thermoforming include: They are flexible and can be used to produce any desired shape and size. : Port You will be speaking with one of our knowledgeable design engineers that will take the time This is because once the design has been confirmed, thermoformed parts can be ready within a month or less. | Affiliate, Product Listing Policy Inconsistent Acrylic part thickness is another problem. completed many thousands of projects. quipped with a temperature controller. How to make the products? Finding the right product to integrate into the workflow should be an easy task. The remedy here is to use a female tool to prevent the webbing. Please inform us of your working material kind, (Max size and Material) or drawings.like acrylic, ABS, PLA, PMMA.PC etc. : After-sales Service Copyright 1996-2022 IndiaMART InterMESH Ltd. All rights reserved. : Type Nevertheless, the requirements for temperature depend on forming conditions like the degree of shaping/stretching and the forming rate. Manufacturing companies use CAD files. You can then place your order depending on the purpose for which the machine is intended and your budget. This can be caused by improper tooling materials selection or inadequate tool surface finishing. station where you will see one of the largest libaries of projects of our past Post sourcing requests and get quotations quickly. 4.Circulating water cooling system by submerged pump, keep the worktable stay in cool condition to protect hand and machine. There are those that are distinctly made to carry out pressure forming or vacuum ones. Pressure forming acrylic sheet can form pieces with vents and louvers. panels- industrial cases-shipping cases acrylic sky lights- Air plane This will result in a failure to produce the desired results. made of square steel, and the main fixture is made, controlled by 4 cylinders separately. It is limited to shape complexity and thin-walled parts. Video Clips | Through this process, they produce surroundings of computer screens, soft transparent keyboard covers, enclosures, and ancillary equipment. interiors commercial signs- truck linersRecommended plastic gauge 3/8"(.95cm) Stay updated to what's new and popular on the market. Raised corners as a result of excessive stress. Acrylic sheet develops stress when the forming rate is excessively fast, and this causes low craze resistance. | A: It is suggested to use big water tank or bucket. It is only ideal for applications that use shallow acrylic parts which are formed into cavities. (951) 741-4822 So many products can be created using vacuum forming, ad the limits are only defined by your creativity. : Product Type How do I choose Acrylic Vacuum Forming Machine? Onetouch A: Yes.Caution: To ensure the power supply is turned off, before cleaning and replairing. Thermoformable Anti Fog Anti Scratch Polycarbonate Sheet, Thermoforming Acrylic: The Ultimate Guide, 11 Great Technologies to Skyrocket Your Football Visor Business, Photochromic: Complete Guide Book to Learn Everything About Photochromic Technology. Including Type, Material, Function and so on. These machines exist in a variety of capacities with different price allocations. vacuum former this model offers heavy to light gauge high detailed vacuum forming Warranty : Processing Technics 8. thermoforming acrylic Advertising equipment,light box.acrylic singn.logo etc, 2.Decoration &redecoration ,furniture,bathtub.wallpaper etc. Acrylic has the ability to resist deformation, but when heated, it becomes elastic and begins to form over a mold.  A family that cares.. Acrylic, PP, PE, PMMA, PVC, PET, ABS.PA, etc. B2-20120091-4, advertising equipment vacuum forming machine, vacuum forming machine thermoforming china sale. Aeronautical manufacturers use this application to make interior trim panels, covers cowlings and internal sections for (NASA) space shuttle. In addition to this, you can also add supplemental heat to the corners. Machine Vaccum Forming Used Form Automatic Positive And Negative Pressure Machine Thermoming Vaccum Forming Machine, Vacuum Machine Thermoforming Vacuum Packaging Machine Date Food Tray Sealing PackIng Thermoforming Vacuum Packaging Machine, Acrylic Vaccum Machine Vacuum Forming Small Vacuum Forming Machine Hot Sell Small Acrylic Vaccum Molding Machine With Cheaper Price Vacuum Formers Forming Machine, Vaccum Machines Vacuum Forming Machine Leadworld Vaccum Packing Machines Kitchen Automatic Vacuum Food Sealer Packaging Forming Vakum Machine For Vaccum Packing, Vacuum Forming Machine Hot Selling Most Popular Dental Lab Vacuum Forming Machine Thermoforming Vacuum Forming Machine, Lightbox 3D Letters Acrylic sign vacuum thermo forming machine, Acrylic Letter 3D sign vacuum thermo forming machine for acrylic sheet molding, 1212 1224 2030 Acrylic Letters Plastic Vacuum Forming Machine for Signage, Small automatic plastic blister container tray vacuum forming machine for chicken quail eggs, 3D car mats Thick sheet vacuum forming machine, Small mini desktop tabletop acrylic pvc plastic vacuum former / thermo vacuum forming machine, Manual semi automatic blister packing seedling tray seeds plastic transparent thick acrylic sheet board vacuum forming machine, Acrylic vacuum forming machine thermoforming for advertising letters, 2020 New Acrylic ABS Plastic Vacuum Former Thermal Forming Machine for Advertising Signage 3D Letter Light Box, Plastic Blister Drawbar Box Vacuum Forming Machine, Mini size cheap price desktop manual acrylic thermo vacuum forming machine with CE, Fair Price Custom Automatic Thick Acrylic Sheet Bathtub Vacuum Forming Making Machine, Mechanical Equipment Blister Machine Packing Automatic Thermoforming Acrylic Vacuum Forming Machine Egg Tray Making Machines, Automatic Advertising Multifunctional Blow-Pressing Suction Acrylic Hydraulic Blister Vacuum Forming Machine, Stable Quality Acrylic ABS PVC thermoforming machine vacuum forming machine for advertising sign/billboard, Mini Desktop Plastic Small Vacuum forming machine for Acrylic, PVC, ABS ,PET etc, Perfect Laser - 3D Acrylic Signs Letters Plastic Wall Panel Multi functional Vacuum Forming Machine, Automatic Plastic Vacuum Forming Machine For Safety Helmet Construction For Sale, acrylic vacuum forming machine Used in the dining box hardware tool thermoforms blister packaging machine, Fast speed mini deep acrylic vacuum forming machine, Semi automatic acrylic bathtub vacuum forming machine thermoforming, Plastic thermoforming machine Acrylic vacuum forming machine, Support Custom Acrylic ABS Vacuum Thermoforming Former Machinery Mini Spa Vacuum Forming Machine, Hengrong ABS acrylic vacuum forming machine for advertising 3d sign logo decoration board making thermoforming, factory supply Acrylic letter vacuum forming machine/Acrylic shaping machine for sale, Direct Manufacturer Single Station Vacuum Forming Blister Acrylic Vacuum Forming Machine for Samples Making, Jing Yi Brand, Alibaba recommend abs vacuum forming machine, YESHINE fully automatic plastic abs pc vacuum carton tray forming machine, Automatic Plastic Acrylic Advertising Letter Making Vacuum Forming Machine. Recommended for the pre-heating and drying of heavy gauge and materials such as It is also determined by thermal conductivity. It produces products with beautiful gradual bends. : Material This feature can make the product more standardized and make manufacture more convenient. Web or unwanted wrinkles usually form around the mold particularly when you use the vacuum method of forming acrylic. Some units are specialized for the sign-making industry, while others lend themselves to art and craft projects like 3D poster creation. Like many manufacturing processes, thermoforming acrylic also has some problems which interfere with its successful process. The factors affecting the choice of material here include functional reasons like fire-related and high heat materials. 17. This application is very relevant here because acrylic can be exposed to UV radiation and elements. 1688.com Naturally, boxes aren't the only use for a acrylic vacuum forming machine. Vacuum forming acrylic sheet technique has the ability to form very large parts. Q: The water temperature will be heated after long time work. A: Yes. Q: There is white foam under heating lamp. we would encourage you, our new customer to review this site and take time to visit our YouTube Finding the right product to integrate into the workflow should be an easy task. vaco formacin caseras termoformadoras formech acrlico mquinas profundidad forming vacuum machine acrylic plastic larger The industry has found this application relevant because they use it to process chocolate molds for special occasions. Sometimes, techniques like power drape forming are used. Table sign is widely used in conference, hotel front desk agent, buffet. Modular engineered post and beam vacuum forming machine series, Supporting all the same equipment capabilities and features expected from a Belovac Belovac has been a family owned and operated company since 1984, and for over three decades we have successfully 6. Because the final product cools against the mold surface under ambient temperature, its finished parts have zero residual stress. This is one of the earliest thermoforming processes dating back to early Egyptian times. It saves up to about 90% of tooling cost as compared to other molding types. forming vacuum thermoforming Subscribe free newsletter to get latest products and discount information. This system offers split second timing and heat control for consistent product Copyright 2005-2022 YN. During drape forming, acrylic sheet is not typically stretched. PVC / Pet / PP / PS/ABS/EVA Automatic Plastic Blister, Cheap PVC PE Pet PC PS PP PMMA HIPS ABS Plastic Sheet Extrusion, Vacuum Oil Purification Machine Manufacturers, Vacuum Distillation Machine Manufacturers. It is small and portable machine, so it can be used in anywhere. acrylics, polycarbonates, and ABS. The single suction mode only needs to customize the male-mold, and the processed corners are rounded; the single pressure mode and the simultaneous pressure suction mode need to customize the female-mold and male-mold at the same time, and makes the characters more vividly. Roll Fed | forming vacuum pmma acrylic thermoforming machine pvc larger 1.Size: 700mm and 1300mm. We offer one standby heating tube for each ABM. Also, the parts that have sharp bends and corners are very difficult to produce. For instance, when the acrylic volume is larger, thermal conductivity is small and therefore the heating time becomes long. Only two models at present.ABM700: applicable length650mmABM1300: applicable length1250mm. In this case, you should add draught angle corners to allow the materials to flow over the mold or pattern. 5.Big worktable ensures evenly heated, no foaming, no deformation, easy to handle. Place the acrylic sheet on the mold surface and fixed using a clamping unit.