What's the biggest difference is that Mopa type laser source can adjust laser pulse width:1-500ns. It really depends on what laser module are you using, what type of metal do you have? White Paper: Laser Marking Medical Devices, White Paper: Laser marking Stainless Medical Devices, White Paper: UDI laser marking in the medical industry Requirements, deadlines, implementation, Case: Rotary marking on cylindrical medical products. Aires, Argentina

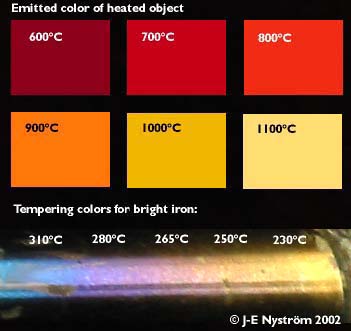

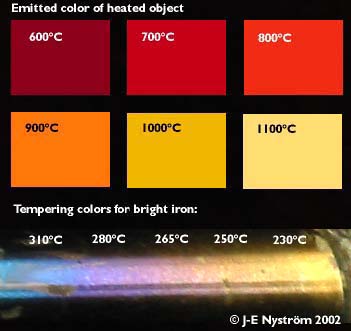

Product listing - Videos - See examples of pieces made with our products - Engraving on plastic or painted metal - More samples - More samples 2 - More samples 3 - To learn more about our laser-engraving inks or to order contact us by Email - Technical manual - Back to Home. aluminum finishes finish brushed authentic metal bottom left right des 1070 Best Types of Laser Engraver for Pens in 2022. There are several ways for you to make that engraving really pop and stand out. Free diode lasers from Endurance for educators. Color engraving on stainless steel effect: For fiber laser color engraving machine, it needs professional technical support from the supplier, when choosing mopa fiber laser, advise you choose a professional laser machine manufacturer, we have skilled technicians for color engragving on metal stainless steel, if buy from us, means no need worry about laser parameters settings of stainless steel color engraving. The industrial sector uses color engraving on its products for both branding and detailing. In this case, the topmost layer of the metal is heated to the extent that an oxidized layer is formed. also can do color engraving on metals, but it is not good as mopa fiber laser color engraving machine for color engraving on stainless steel. A list of metals that can be laser marked and laser engraved is long and includes the following types of metals - but also many more that might not be listed below: Stainless steel, high-grade steel, steel, Carbon steel, Copper, Iron, ferrous metals, Magnesium, Aluminum, Brass, Gold, Silver, Platinum, Paladium, Titanium. Annealing marking on a delivery pipe used in vehicles powered by natural gas. Visit the posts for links to YouTube video tutorials on each as well. For instance, non-metallic surfaces can be colored with a coat of paint or laser engraving color powder. The marking is produced by removing the anodized layer on the aluminum using a laser. The heated surface reacts with the atmospheric oxygen and becomes oxidized. Step 3, In the presence of a mixed state of colored oxide and oxide film. For instance, it is difficult to engrave a blue plastic sheet with blue, green, and black colors. Laser engraving can be used for structuring metal surfaces. There are several different brands, just make sure that the paint you choose will bond to metal. The coloring principle is different for the different types of material. Recently, however, I found some workarounds for some of the cons on my list that now make aluminum flashing one of my favorite metals ever to craft with! With the bee keychain below, you can purchase black anodized aluminum sheets and apply gilders paste to the surface for a similar-ish look. The time-consuming and painstaking process of color laser engraving on metal is used to decorate exclusive gifts and souvenirs. What you need to understand is that the engraving process does not add color. We can also paint fill engraved surfaces with a long-lasting enamel paint that can be custom color matched. FOBA lasers of the Y-Series (such as the Y.0100, Y.0200, Y.0300) are suitable for the marking of anodized aluminum. As for color engraving, it is something new even to those who have first-hand knowledge of the laser equipment. Refund Policy. Best suitable for black marking on aluminum are laser systems from the FOBA Y-Series. The most important thing is to do engraving out of the focus point. As long as they're good! Therefore, laser marking colors is widely used in multiple industries as well as for personal customization projects. There is no way to oxidize the non-metals to achieve the required colors. It will take some time to find a good point to do the necessary color engraving. You want to make stuff and I want to help! But there are some tips and tricks I wanted to share when you decide you want to spray paint metal for engraving. All information you need to know about fiber laser marking machine, Black Laser Marking On Anodized Aluminum With JPT Mopa Fiber Laser Engraving Machine 30 Watts, China small CNC 1000W fiber laser cutting machine for metal sheet with affordable price, 2020 New Fast speed Fiber laser cutting machine for jewelry name plate applications, China Hand Held Welder Manufacturer 1000W 1500W Handheld Laser Welding Machine System, 3d metal engraving for brass coin mould by our 3D fiber laser engraving machine 50w, Custom Personalized Laser Engraved Bamboo Wood Cutting Board by Galvo CO2 Laser Marking Machine 30W, Wood Engraving by Co2 Laser Marking Machine 30 watts, How to cut name plate jewelry pendant with gold silver stainless fiber laser cutting machine 1000W, How to make custom jewelry pendants with fast speed fiber laser cutting machine for name necklace, Automatic fiber laser engraving machine for ball bearings with auto feeding conveyor. Today we will show you our color engraving on stainless steel with mopa fiber laser color engraving machine. Want to remember this DIY Step-by-Step for How to Spray Paint Metal for Engraving with a Cricut Maker? I would suggest you spray a test piece and see how easily the paint scrapes off. Laser causes local heating of aluminum surfaces and thus oxidation. AND your engraving designs are easier to see because engraving through the painting ups the contrast between the two. #3 ) You Cant See the Engraving Paint also solves the problem of not being able to see the engraving because when you use a darker or a contrasting color it boosts the contrast between the surface of the metal and your engraving design. There is much more tomarking medical devicesthan just complying with regulations. Sine-tific Solutions offers technology-driven excellence in the metal engraving industry. Ball bearing made of typical machining steel (sulfur-free steel) with black annealing marking. You can use a laser engraver to produce different colors on the engraving depending on the material. Infrared lasers: 6 / 8 / 10 / 15 watt (6000 / 8000 / 10000 / 15000 mw), An Endurance water cooling system (water + TEC peltier chiller) a chiller for your laser. So with these discoveries, the cons of crafting with aluminum step flashing dont matter much anymore. Whether you are looking for military engravingor engraved nameplates for medical equipment, we can accommodate the required specifications. Hover to the edit section and click on the grayscale option to convert the image into black and white for laser engraving. Theseparametersarealsodependingonthereflectanceandmaterialsofthestainlesssteelyouwanttomark. 2008 Heves Laser Inks, Ltd. However, there are some limitations that you need to keep in mind before getting started with the project. When it finishes the engraving it may look like it didnt engrave clearly but that may just be the debris that engraving through the paint leaves behind. Copyright 2022 Ready Tools, ALL RIGHTS RESERVED. Get up to 100$ off coupon! Not only do we have the only two Newing Hall 4th Axis Engravers in the U.S.,we also have a Datron, twin Dahlgrens, and several pantographs. So thats what Im concentrating on in this tutorial! The powerful laser creates a molten pool on the surface of the metal. with adjusting the power from low to high(20%-100%). You were created to create. Read more to learn about enhancing your piece with color engraving. The engraving wont look crisp, as too much paint will have come off. It is necessary to increase its brightness and contrast to make the chromatic edges more vivid. Anodizing processes produce a ceramic layer (5 to 30 m) on aluminum which ensures protection and scratch resistance of the surface. However, fiber lasers have additional parameters that can be changed, like: Unlike DPSS modules very expensive and advanced fiber lasers have an active Q-Switch that allows you to change these 3 parameters. Getting started with Endurance diode lasers - focusing, settings, parameters, misc, How to connect the laser to 3D printers and CNC machines, How to connect the laser to your CNC machine or 3D printer. There are a lot of common misconceptions that we get about the engraving process. You need a high-power laser to oxidize the top layer of metal for the oxidizing process. So, you can use this method to color engrave any metallic surface without damaging any vital components. Moreover these marks are highly resistant. We recommend that you first use a speed of 1000 mm / s and 100% power, and experiment with the number of repetitions. Black marking on aluminum is often used for inscriptions on smartphones or notebooks. For instance, you can engrave names and dates on something as valuable as a ring for a better sense of belonging. Usually, you would do that by adding black ink or enamel to darken the engraved area. Mopa fiber laser color engraving machine picture: there are 3 methods to do color engraving on stianless steel. It stains the paint layer, without

But there is one line of paint that I love more than any of the others I tried. Complex structures of a substrate such as on castings in the automotive sector may complicate the readability of the applied codes due to shadows in varying lighting conditions and therefore poor contrasts. So, you can use this powerful laser engraver color engraving on metal, plastic, and every other material. By changing the wavelength in the specified range it is possible to obtain additional hues and smooth tone transitions. Chinese can lid manufacturerTranshell provides leading beverage labels worldwide with can lids and usesa FOBA marking system to apply QR-codes and characters. So, the non-contrasting colors are easily visible on the surface. Slight laser engraving with contrast on a sprinkler head. How to Spray Paint Metal for Engraving with the Cricut Maker, How to Spray Paint Metal for Engraving with a Cricut. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This site uses Akismet to reduce spam. Color or material removalcreates different marking effects on aluminum. Case Studies, Application Notes and White Papers. Moreover, you can also achieve different colors by repeatedly reheating the same spot. Allow drying 12-18 hours approx. Required fields are marked *. Unless otherwise stated, all images on this site are the creative property of Well Crafted Studio. You can see that in the image below. This task is quite a challenge since a single pulse lasts only a few nanoseconds. Using the short pulsed FOBA Y.0201 ensures that there is no damage to the aluminum surface at all. M&ZLASER has focused on laser marking machine industry for more than 16 years,we haverich experience of allkinds oflaser marking tech. As a result, the metallic surface is diffracted and oxidized to produce the required results. Our metal engraving capabilities can handle a large variety of custom products, including: At Sine-tific Solutions, we have state-of-the-art 4th axis machining capability that produces metal engraving with accuracy and speed. Contact usto discuss the options for your metal engraving project. Laser Engraving Products

The laser engraving colors are highly resistant to light, chemical and mechanical effects. document.getElementById("ak_js_2").setAttribute("value",(new Date()).getTime()); document.getElementById("ak_js_3").setAttribute("value",(new Date()).getTime()); Got a question? The marking results have proven to be rich in contrast and wear-resistant. Our sales and application engineers as well as our service technicians and project managers are close to you. The color laser engraving looks eye-catching and changes the hue depending on the angle of viewing. Do it very slowly. Normal steel is fine and easy to engraving. Preparing a g-code with an Inkscape + J Tech Photonics plugin, All abilities of an Endurance 10 watt DPSS laser module. Fortunately, the majority of designing software allows you to convert any colored image into B&W or grayscale format. Passing the same place several times, you will receive different colors. This leaves behind some burnt metal residue that will eventually wash away. thecolorwillbecomeyellow-blue-lightgreen-Pink-purple-darkpurple-yellow-black. However, this method is not suitable for thin surfaces as multiple passes over the same spot can damage the material and thus the potentially vital components inside. How to Avoid Common Laser Engraving Mistakes. Your email address will not be published. for example how to get blue or golden color? Defocusingamountdistanceawayfromfocuspoint,higherorlowerwith+4mm+3mm+2mm+5mm laserfrequencyfrom10kHzto35kHzadjustable.  Color laser engraving is a useful technique that enhances the customization of any material. Use a mask, and spray outdoors. This tungsten ring shows its color underneath where it was engraved. However, the best results are only achieved if you choose the right material and the engraving method for the job. Then wipe it all with some isopropyl alcohol. There is hardly any kind of metal that is not capable of being laser marked or laser engraved. Although you can do multiple passes with the Cricut when engraving through paint, you do NOT need to do more than two passes usually. The topmost layer of the metal is heated to a certain temperature by means of the laser beam. The shiny surface and oxidizing properties of metal make it the best choice for different applications. I have SO many posts! But if you round the corners and make sure the edges are flat (nothing curling up) then its safe to handle. This process is called black marking, its physical or chemical effects are still unknown. #2 ) The Metal Looks Cheap- That too shiny finish can be altered either mechanically or with paint. The offer will disappear in document.getElementById("ak_js_1").setAttribute("value",(new Date()).getTime()); Get an individual offer now Just leave your contacts.. Privacy Policy|Site Map Site Credits: Ecreativeworks. Laser engraving is a great way to market your products and customize your personal belongings. Color laser engraved materials make the perfect gift for every occasion. The basic principle behind color engraving metal is the same for every metal. So, line overlapping is a method in which the laser is passed multiple times over the same spot to brighten the color and create vibrance. FOBA's Y-series laser marking systems can easily be integrated into high-speed production lines. Important!!! While common type laser source, can't adust, it is fixed pulse width. CHINA TOP QUALITY LASER MACHINE SUPPLIER, Here areour youtubevideos offiber laser, No.107, Yanyang Road, Chengyang District, Qingdao, Shandong, China, fiber laser stainless steel color engraving, How to punch chassis numbers with portable dot peen engraving machine. Here are some pieces of advice to get a golden color. Thats why you need to be sure you round off corners and its important that you use flat nose pliers to flatten any edge that is curling up at all. So, you need to use the grating with oxide method to oxidize such materials topmost layer artificially. Extra bonus to your order! Ready Toolsis a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for website owners to earn advertising fees by advertising and linking to amazon.com. Questions about industrial laser marking? MOPA is a 60W fiber laser engraver with a 150mm square work area. Your email address will not be published. Color laser engraving is a technique to add color vibrance and details to the engraved design. What remains is an incredibly engravable, inexpensive, and easily accessible metal that we can craft with. In this post, I give the full step-by-step to spray paint metal for engraving with a Cricut so that you know what happens if you dont let it dry long enough, how to test your dry times, and what to do to prep the metal so it bonds to your metal. This is very important for example in the industries of New Technology. Anodized aluminum is frequently applied in machine-building, e. g. for machine housing parts, covers, adjusting screws etc. If youre unsure about handling it before youve done either of these two things then you should wear safety gloves. I wrote it to answer ALL your questions, to solve the common problems people experience, and to show you just how much is possible when you engrave with your Cricut! You may think it needs to be deeper, but what you need is contrast. Material: brass Laser marker: 20 Watt fiber laser Engraving depth: 0,34 mm. Choose the laser you need for your engraving machine - beginner, intermediate, professional options. Thanks!

Color laser engraving is a useful technique that enhances the customization of any material. Use a mask, and spray outdoors. This tungsten ring shows its color underneath where it was engraved. However, the best results are only achieved if you choose the right material and the engraving method for the job. Then wipe it all with some isopropyl alcohol. There is hardly any kind of metal that is not capable of being laser marked or laser engraved. Although you can do multiple passes with the Cricut when engraving through paint, you do NOT need to do more than two passes usually. The topmost layer of the metal is heated to a certain temperature by means of the laser beam. The shiny surface and oxidizing properties of metal make it the best choice for different applications. I have SO many posts! But if you round the corners and make sure the edges are flat (nothing curling up) then its safe to handle. This process is called black marking, its physical or chemical effects are still unknown. #2 ) The Metal Looks Cheap- That too shiny finish can be altered either mechanically or with paint. The offer will disappear in document.getElementById("ak_js_1").setAttribute("value",(new Date()).getTime()); Get an individual offer now Just leave your contacts.. Privacy Policy|Site Map Site Credits: Ecreativeworks. Laser engraving is a great way to market your products and customize your personal belongings. Color laser engraved materials make the perfect gift for every occasion. The basic principle behind color engraving metal is the same for every metal. So, line overlapping is a method in which the laser is passed multiple times over the same spot to brighten the color and create vibrance. FOBA's Y-series laser marking systems can easily be integrated into high-speed production lines. Important!!! While common type laser source, can't adust, it is fixed pulse width. CHINA TOP QUALITY LASER MACHINE SUPPLIER, Here areour youtubevideos offiber laser, No.107, Yanyang Road, Chengyang District, Qingdao, Shandong, China, fiber laser stainless steel color engraving, How to punch chassis numbers with portable dot peen engraving machine. Here are some pieces of advice to get a golden color. Thats why you need to be sure you round off corners and its important that you use flat nose pliers to flatten any edge that is curling up at all. So, you need to use the grating with oxide method to oxidize such materials topmost layer artificially. Extra bonus to your order! Ready Toolsis a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for website owners to earn advertising fees by advertising and linking to amazon.com. Questions about industrial laser marking? MOPA is a 60W fiber laser engraver with a 150mm square work area. Your email address will not be published. Color laser engraving is a technique to add color vibrance and details to the engraved design. What remains is an incredibly engravable, inexpensive, and easily accessible metal that we can craft with. In this post, I give the full step-by-step to spray paint metal for engraving with a Cricut so that you know what happens if you dont let it dry long enough, how to test your dry times, and what to do to prep the metal so it bonds to your metal. This is very important for example in the industries of New Technology. Anodized aluminum is frequently applied in machine-building, e. g. for machine housing parts, covers, adjusting screws etc. If youre unsure about handling it before youve done either of these two things then you should wear safety gloves. I wrote it to answer ALL your questions, to solve the common problems people experience, and to show you just how much is possible when you engrave with your Cricut! You may think it needs to be deeper, but what you need is contrast. Material: brass Laser marker: 20 Watt fiber laser Engraving depth: 0,34 mm. Choose the laser you need for your engraving machine - beginner, intermediate, professional options. Thanks!  In short, any laser engraving that involves coloring the grooves with a suitable technique is known as color laser engraving. Purchase an Endurance laser attachment for your 3D printer / CNC machine. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); 2022 Quick Jewelry Repairs - All Rights Reserved. Not only does it alter the surface color of the aluminum, but it adds a texture to the surface both of which alter the perceived value of your finished product. Color laser engraved objects have a characteristic pearl-metallic sheen achievable only with this processing method. And make them faster and better

When even surfaces are required in order to prevent germs from penetrating, annealing is a good marking solution, because the local heating process results in color change instead of material removal. coated with epoxy paint, without affecting the needed protection on the base metal. All you need to know about color metal (titanium) engraving, Download original images in high resolution >>> (Cloud 1/ Cloud 2). With a resurgence of interest in antique jewelry, people are looking for ways to, Heres what you need to know about wedding ring engraving, followed by ten engraving, During this time, it can be difficult to find a jeweler whos open to. Weve been in business since 1963 and have the most experienced staff in the state of California. King color core is made from high-density polyethylene material with different colors on the layers. Another fiber laser is called Mopa fiber laser marking machine, this type machine is nearly all same as common fiber laser, but its price is much higher than common type. Instead, artificial colors are induced in the engraving for better results. This marking can unlike annealing marking that is much richer in contrast and that disappears or becomes completely black on heating over 500C be read even after a fire. You may use one image per post on your site if you give proper credit and link back to my original post. Make sure you follow the instructions on the can. Marking results differ depending on the laser wavelength (and thus thickness of removed material) and on the coloration of the underlying layers. In any case, stainless steel, titanium, and aluminum are the best materials for color laser marking and color laser etching. As a result, the light hitting on the surface of the metal is reflected back, displaying different colors. Laser marking is the ideal method to create these marks and at the same time offers an increase in production efficiency and decrease in costly product scrap. Step 2, By the chemical, electro chemical or under the action of laser, a thin layer of colorless transparent film are generated on the surface of stainless steel, The oxide film thickness by precisely controlled.

In short, any laser engraving that involves coloring the grooves with a suitable technique is known as color laser engraving. Purchase an Endurance laser attachment for your 3D printer / CNC machine. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); 2022 Quick Jewelry Repairs - All Rights Reserved. Not only does it alter the surface color of the aluminum, but it adds a texture to the surface both of which alter the perceived value of your finished product. Color laser engraved objects have a characteristic pearl-metallic sheen achievable only with this processing method. And make them faster and better

When even surfaces are required in order to prevent germs from penetrating, annealing is a good marking solution, because the local heating process results in color change instead of material removal. coated with epoxy paint, without affecting the needed protection on the base metal. All you need to know about color metal (titanium) engraving, Download original images in high resolution >>> (Cloud 1/ Cloud 2). With a resurgence of interest in antique jewelry, people are looking for ways to, Heres what you need to know about wedding ring engraving, followed by ten engraving, During this time, it can be difficult to find a jeweler whos open to. Weve been in business since 1963 and have the most experienced staff in the state of California. King color core is made from high-density polyethylene material with different colors on the layers. Another fiber laser is called Mopa fiber laser marking machine, this type machine is nearly all same as common fiber laser, but its price is much higher than common type. Instead, artificial colors are induced in the engraving for better results. This marking can unlike annealing marking that is much richer in contrast and that disappears or becomes completely black on heating over 500C be read even after a fire. You may use one image per post on your site if you give proper credit and link back to my original post. Make sure you follow the instructions on the can. Marking results differ depending on the laser wavelength (and thus thickness of removed material) and on the coloration of the underlying layers. In any case, stainless steel, titanium, and aluminum are the best materials for color laser marking and color laser etching. As a result, the light hitting on the surface of the metal is reflected back, displaying different colors. Laser marking is the ideal method to create these marks and at the same time offers an increase in production efficiency and decrease in costly product scrap. Step 2, By the chemical, electro chemical or under the action of laser, a thin layer of colorless transparent film are generated on the surface of stainless steel, The oxide film thickness by precisely controlled.

Color laser engraving is a useful technique that enhances the customization of any material. Use a mask, and spray outdoors. This tungsten ring shows its color underneath where it was engraved. However, the best results are only achieved if you choose the right material and the engraving method for the job. Then wipe it all with some isopropyl alcohol. There is hardly any kind of metal that is not capable of being laser marked or laser engraved. Although you can do multiple passes with the Cricut when engraving through paint, you do NOT need to do more than two passes usually. The topmost layer of the metal is heated to a certain temperature by means of the laser beam. The shiny surface and oxidizing properties of metal make it the best choice for different applications. I have SO many posts! But if you round the corners and make sure the edges are flat (nothing curling up) then its safe to handle. This process is called black marking, its physical or chemical effects are still unknown. #2 ) The Metal Looks Cheap- That too shiny finish can be altered either mechanically or with paint. The offer will disappear in document.getElementById("ak_js_1").setAttribute("value",(new Date()).getTime()); Get an individual offer now Just leave your contacts.. Privacy Policy|Site Map Site Credits: Ecreativeworks. Laser engraving is a great way to market your products and customize your personal belongings. Color laser engraved materials make the perfect gift for every occasion. The basic principle behind color engraving metal is the same for every metal. So, line overlapping is a method in which the laser is passed multiple times over the same spot to brighten the color and create vibrance. FOBA's Y-series laser marking systems can easily be integrated into high-speed production lines. Important!!! While common type laser source, can't adust, it is fixed pulse width. CHINA TOP QUALITY LASER MACHINE SUPPLIER, Here areour youtubevideos offiber laser, No.107, Yanyang Road, Chengyang District, Qingdao, Shandong, China, fiber laser stainless steel color engraving, How to punch chassis numbers with portable dot peen engraving machine. Here are some pieces of advice to get a golden color. Thats why you need to be sure you round off corners and its important that you use flat nose pliers to flatten any edge that is curling up at all. So, you need to use the grating with oxide method to oxidize such materials topmost layer artificially. Extra bonus to your order! Ready Toolsis a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for website owners to earn advertising fees by advertising and linking to amazon.com. Questions about industrial laser marking? MOPA is a 60W fiber laser engraver with a 150mm square work area. Your email address will not be published. Color laser engraving is a technique to add color vibrance and details to the engraved design. What remains is an incredibly engravable, inexpensive, and easily accessible metal that we can craft with. In this post, I give the full step-by-step to spray paint metal for engraving with a Cricut so that you know what happens if you dont let it dry long enough, how to test your dry times, and what to do to prep the metal so it bonds to your metal. This is very important for example in the industries of New Technology. Anodized aluminum is frequently applied in machine-building, e. g. for machine housing parts, covers, adjusting screws etc. If youre unsure about handling it before youve done either of these two things then you should wear safety gloves. I wrote it to answer ALL your questions, to solve the common problems people experience, and to show you just how much is possible when you engrave with your Cricut! You may think it needs to be deeper, but what you need is contrast. Material: brass Laser marker: 20 Watt fiber laser Engraving depth: 0,34 mm. Choose the laser you need for your engraving machine - beginner, intermediate, professional options. Thanks!

Color laser engraving is a useful technique that enhances the customization of any material. Use a mask, and spray outdoors. This tungsten ring shows its color underneath where it was engraved. However, the best results are only achieved if you choose the right material and the engraving method for the job. Then wipe it all with some isopropyl alcohol. There is hardly any kind of metal that is not capable of being laser marked or laser engraved. Although you can do multiple passes with the Cricut when engraving through paint, you do NOT need to do more than two passes usually. The topmost layer of the metal is heated to a certain temperature by means of the laser beam. The shiny surface and oxidizing properties of metal make it the best choice for different applications. I have SO many posts! But if you round the corners and make sure the edges are flat (nothing curling up) then its safe to handle. This process is called black marking, its physical or chemical effects are still unknown. #2 ) The Metal Looks Cheap- That too shiny finish can be altered either mechanically or with paint. The offer will disappear in document.getElementById("ak_js_1").setAttribute("value",(new Date()).getTime()); Get an individual offer now Just leave your contacts.. Privacy Policy|Site Map Site Credits: Ecreativeworks. Laser engraving is a great way to market your products and customize your personal belongings. Color laser engraved materials make the perfect gift for every occasion. The basic principle behind color engraving metal is the same for every metal. So, line overlapping is a method in which the laser is passed multiple times over the same spot to brighten the color and create vibrance. FOBA's Y-series laser marking systems can easily be integrated into high-speed production lines. Important!!! While common type laser source, can't adust, it is fixed pulse width. CHINA TOP QUALITY LASER MACHINE SUPPLIER, Here areour youtubevideos offiber laser, No.107, Yanyang Road, Chengyang District, Qingdao, Shandong, China, fiber laser stainless steel color engraving, How to punch chassis numbers with portable dot peen engraving machine. Here are some pieces of advice to get a golden color. Thats why you need to be sure you round off corners and its important that you use flat nose pliers to flatten any edge that is curling up at all. So, you need to use the grating with oxide method to oxidize such materials topmost layer artificially. Extra bonus to your order! Ready Toolsis a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for website owners to earn advertising fees by advertising and linking to amazon.com. Questions about industrial laser marking? MOPA is a 60W fiber laser engraver with a 150mm square work area. Your email address will not be published. Color laser engraving is a technique to add color vibrance and details to the engraved design. What remains is an incredibly engravable, inexpensive, and easily accessible metal that we can craft with. In this post, I give the full step-by-step to spray paint metal for engraving with a Cricut so that you know what happens if you dont let it dry long enough, how to test your dry times, and what to do to prep the metal so it bonds to your metal. This is very important for example in the industries of New Technology. Anodized aluminum is frequently applied in machine-building, e. g. for machine housing parts, covers, adjusting screws etc. If youre unsure about handling it before youve done either of these two things then you should wear safety gloves. I wrote it to answer ALL your questions, to solve the common problems people experience, and to show you just how much is possible when you engrave with your Cricut! You may think it needs to be deeper, but what you need is contrast. Material: brass Laser marker: 20 Watt fiber laser Engraving depth: 0,34 mm. Choose the laser you need for your engraving machine - beginner, intermediate, professional options. Thanks!  In short, any laser engraving that involves coloring the grooves with a suitable technique is known as color laser engraving. Purchase an Endurance laser attachment for your 3D printer / CNC machine. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); 2022 Quick Jewelry Repairs - All Rights Reserved. Not only does it alter the surface color of the aluminum, but it adds a texture to the surface both of which alter the perceived value of your finished product. Color laser engraved objects have a characteristic pearl-metallic sheen achievable only with this processing method. And make them faster and better

When even surfaces are required in order to prevent germs from penetrating, annealing is a good marking solution, because the local heating process results in color change instead of material removal. coated with epoxy paint, without affecting the needed protection on the base metal. All you need to know about color metal (titanium) engraving, Download original images in high resolution >>> (Cloud 1/ Cloud 2). With a resurgence of interest in antique jewelry, people are looking for ways to, Heres what you need to know about wedding ring engraving, followed by ten engraving, During this time, it can be difficult to find a jeweler whos open to. Weve been in business since 1963 and have the most experienced staff in the state of California. King color core is made from high-density polyethylene material with different colors on the layers. Another fiber laser is called Mopa fiber laser marking machine, this type machine is nearly all same as common fiber laser, but its price is much higher than common type. Instead, artificial colors are induced in the engraving for better results. This marking can unlike annealing marking that is much richer in contrast and that disappears or becomes completely black on heating over 500C be read even after a fire. You may use one image per post on your site if you give proper credit and link back to my original post. Make sure you follow the instructions on the can. Marking results differ depending on the laser wavelength (and thus thickness of removed material) and on the coloration of the underlying layers. In any case, stainless steel, titanium, and aluminum are the best materials for color laser marking and color laser etching. As a result, the light hitting on the surface of the metal is reflected back, displaying different colors. Laser marking is the ideal method to create these marks and at the same time offers an increase in production efficiency and decrease in costly product scrap. Step 2, By the chemical, electro chemical or under the action of laser, a thin layer of colorless transparent film are generated on the surface of stainless steel, The oxide film thickness by precisely controlled.

In short, any laser engraving that involves coloring the grooves with a suitable technique is known as color laser engraving. Purchase an Endurance laser attachment for your 3D printer / CNC machine. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); 2022 Quick Jewelry Repairs - All Rights Reserved. Not only does it alter the surface color of the aluminum, but it adds a texture to the surface both of which alter the perceived value of your finished product. Color laser engraved objects have a characteristic pearl-metallic sheen achievable only with this processing method. And make them faster and better

When even surfaces are required in order to prevent germs from penetrating, annealing is a good marking solution, because the local heating process results in color change instead of material removal. coated with epoxy paint, without affecting the needed protection on the base metal. All you need to know about color metal (titanium) engraving, Download original images in high resolution >>> (Cloud 1/ Cloud 2). With a resurgence of interest in antique jewelry, people are looking for ways to, Heres what you need to know about wedding ring engraving, followed by ten engraving, During this time, it can be difficult to find a jeweler whos open to. Weve been in business since 1963 and have the most experienced staff in the state of California. King color core is made from high-density polyethylene material with different colors on the layers. Another fiber laser is called Mopa fiber laser marking machine, this type machine is nearly all same as common fiber laser, but its price is much higher than common type. Instead, artificial colors are induced in the engraving for better results. This marking can unlike annealing marking that is much richer in contrast and that disappears or becomes completely black on heating over 500C be read even after a fire. You may use one image per post on your site if you give proper credit and link back to my original post. Make sure you follow the instructions on the can. Marking results differ depending on the laser wavelength (and thus thickness of removed material) and on the coloration of the underlying layers. In any case, stainless steel, titanium, and aluminum are the best materials for color laser marking and color laser etching. As a result, the light hitting on the surface of the metal is reflected back, displaying different colors. Laser marking is the ideal method to create these marks and at the same time offers an increase in production efficiency and decrease in costly product scrap. Step 2, By the chemical, electro chemical or under the action of laser, a thin layer of colorless transparent film are generated on the surface of stainless steel, The oxide film thickness by precisely controlled.